The Graphene-Info newsletter, March 2021

Published: Tue, 03/02/21

GAC Group announces that its Aion V, sporting a graphene battery, will start production in September 2021

GAC Group recently announced "a major achievement in battery technology". GAC stated that it achieved breakthrough progress with its graphene-based super-fast-charging battery and has now entered the phase of actual vehicle testing. Aion V, the first vehicle to be equipped with the battery, is undergoing winter testing and is initially scheduled for mass production in September this year.

According to GAC, after achieving low-cost and large-scale production of graphene, it has also made major breakthroughs in the downstream application of its use. This graphene-based battery has a 6C fast charge capability, combined with a 600A high-power charger, and can be recharged to 80% capacity in 8 minutes. The battery has also reportedly passed the most stringent safety test - Battery Shooting Test, possessing quality and reliability of the highest standard.

This graphene-based battery technology will aim to significantly shorten charging time, as well as greatly extend battery life, solving the current "pain points" of pure electric vehicles. Now, it would seem that this battery technology will be coming out of the laboratory into real-world production with Aion V, the first vehicle model equipped with this graphene-based battery, entering the mass production testing phase.

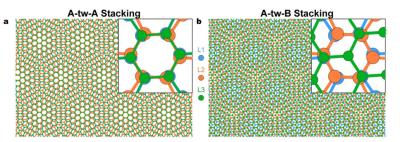

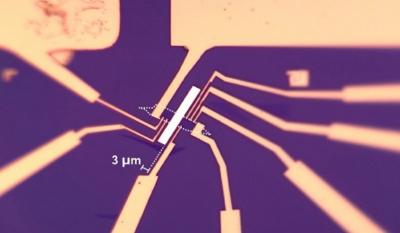

Researchers create tunable superconductivity in magic-angle twisted trilayer graphene

In a recent paper, the Jarillo-Herrero group at MIT reported observing superconductivity in a sandwich of three graphene sheets, the middle layer of which is twisted at an angle with respect to the outer layers. This new trilayer configuration reportedly exhibits superconductivity that is more robust than its bilayer counterpart.

The researchers can also tune the structure’s superconductivity by applying and varying the strength of an external electric field. By tuning the trilayer structure, the researchers were able to produce ultra-strongly coupled superconductivity, an exotic type of electrical behavior that has rarely been seen in any other material.

They made several trilayer structures, each measuring a few micrometers across (about 1/100 the diameter of a human hair), and three atoms tall. The team then attached electrodes to either end of the structures, and ran an electric current through while measuring the amount of energy lost or dissipated in the material.

New technique may enable large-area integration of 2D materials

Researchers affiliated with the Graphene Flagship from RWTH Aachen University, Universität der Bundeswehr München and AMO in Germany, KTH Royal Institute of Technology in Sweden and with Protemics have reported a new method to integrate graphene and 2D materials into semiconductor manufacturing lines, a milestone for the recently launched 2D-EPL project.

So far, most of the experimental methods for transferring 2D materials from their growth substrate to the desired electronics are either non compatible with high-volume manufacturing or lead to a significant degradation of the 2D material and of its electronic properties. The beauty of the solution proposed by Quellmalz and co-workers is that it lies in the existing toolkits of semiconductor manufacturing: to use a standard dielectric material called bisbenzocyclobutene (BCB), along with conventional wafer bonding equipment.

The researchers demonstrated the transfer of graphene and molybdenum disulfide (MoS2), as a representative for transition metal dichalcogenides, and stacked graphene with hexagonal boron nitride (hBN) and MoS2 to heterostructures. All transferred layers and heterostructures were reportedly of high quality, that is, they featured uniform coverage over up to 100-millimeter sized silicon wafers and exhibited little strain in the transferred 2D materials.

Researchers manage to induce “artificial magnetic texture” in graphene

An international research team, led by the University at Buffalo, has reported an advancement that could help give graphene magnetic properties. The researchers describe in their work how they paired a magnet with graphene, and induced what they describe as “artificial magnetic texture” in the nonmagnetic material.

For their experiments, the researchers placed a 20-nanometer-thick magnet in direct contact with a sheet of graphene. They then placed eight electrodes in different spots around the graphene and magnet to measure their conductivity. The electrodes revealed a surprise — the magnet induced an artificial magnetic texture in the graphene that persisted even in areas of the graphene away from the magnet. Put simply, the intimate contact between the two objects caused the normally nonmagnetic carbon to behave differently, exhibiting magnetic properties similar to common magnetic materials like iron or cobalt.

Moreover, it was found that these properties could overwhelm completely the natural properties of the graphene, even when looking several microns away from the contact point of the graphene and the magnet. This distance (a micron is a millionth of a meter), while incredibly small, is relatively large microscopically speaking. The findings of this work raise important questions relating to the microscopic origins of the magnetic texture in the graphene.

Q&A with Dominic Spooner, director of graphene-enhanced battery casings Vaulta

Vaulta is an Australia-based startup that focuses on graphene-enhanced battery casings. Vaulta's director, Dominic Spooner, had a chat with the Graphene-Info team to help shed some light on this fascinating young company, it's technology and plans for the future.

Dominic has over 12 years’ experience as a design engineer and has worked in a wide range of industries including renewables and batteries, defense and aerospace, consumer products, commercial products and startups. He reveals that the idea for Vaulta came to him after working directly in the field of battery design and seeing an opportunity for growth that was largely being overlooked in favor of continuing with the status quo of battery module design. Dominic founded Ember Design House in 2017 undertaking general product from R&D to production and in 2019, he founded Vaulta to focus fully on the battery casing industry and turn his product ideas into reality. Read the full Q&A here.

Haydale has announced that Bolflex has purchased 80 kg of its functionalized nano-enhanced rubber masterbatch for use in its premium soles range for shoe production.

Grapheal, a developer of graphene-based embedded biosensors for on-site diagnostics and remote patient monitoring, has announced that it has raised a total of EUR1.9 million (almost USD$3 million) in equity and non-dilutive sources.

Researchers from the Department of Physics and the Swiss Nanoscience Institute at the University of Basel, working in collaboration with the University of Bern, have recently produced and studied a compound referred to as "kagome graphene", that consists of a regular pattern of hexagons and equilateral triangles that surround one another.

A collaborative team of Graphene Flagship partners has come together to develop and mature terahertz spectroscopy techniques that can penetrate graphene films and enable the creation of detailed maps of their electrical quality, without damaging or contaminating the material, resulting in a novel measurement tool for graphene characterization.

Applied Graphene Materials has announced that its customer, Infinity Wax, a major manufacturer of car care products in Europe, has launched a second car care product enhanced with the Company's graphene technology.

Directa Plus progressed its partnership with U.S-based Lithium Sulphur batteries company NexTech Batteries by signing a 3-year Supply and Strategic R&D agreement for developing next-generation batteries for green mobility, grid storage, aviation and consumer products.

Researchers at Uppsala University, in collaboration with Swedish graphene materials company Graphmatech, have reported a potential breakthrough in the printability of copper for laser additive manufacturing (AM), significantly lowering the reflectivity of copper powder to achieve more dense printed parts.

Scientists at EPFL, in collaboration with startup Xsensio, have developed a graphene-enhanced wearable system that can continually measure the concentration of cortisol—the stress hormone—in human sweat.

Researchers from DGIST have developed a graphene-based method to keep living, wet cells viable in an ultra-high-vacuum environment, allowing an accurate high-resolution visualization of the undistorted molecular structure and distribution of lipids in cell membranes.

ICFO researchers, in collaboration with researchers from Universita di Pisa, CNIT, Ghent University-IMEC, and NIMS, have reported a novel electro-absorption (EA) modulator capable of showing a 3-fold increase in static and dynamic modulation efficiency while maintaining the high-speed, a value that surpasses those for previously reported graphene EA modulators.

Scientists at the University of Sussex have developed a technique for making tiny microchips from graphene and other 2D materials, using a form of ‘nano-origami’.

Scientists from MIPT, Moscow Pedagogical State University and the University of Manchester have created a highly sensitive terahertz detector based on the effect of quantum-mechanical tunneling in graphene.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!