The Graphene-Info newsletter, September 2020

Published: Tue, 09/01/20

New technique allows for processing surfaces on an atomic scale

Researchers at TU Wien designed a nano-structuring method, with which certain layers of a material can be perforated with extreme precision while others are left completely untouched, even though the projectile penetrates all layers. This is made possible with the help of highly charged ions - they can be used to selectively process the surfaces of novel 2D material systems, for example to anchor certain metals on them, which can then serve as catalysts.

"We investigated a combination of graphene and molybdenum disulfide. The two layers of material are brought into contact and then adhere to each other by weak van der Waals forces," says Dr. Janine Schwestka from the Institute of Applied Physics at TU WIen and first author of the current publication. "Graphene is a very good conductor, molybdenum disulphide is a semiconductor, and the combination could be interesting for the production of new types of data storage devices."

Understanding the "coffee ring effect" leads to better graphene and 2D inks

Researchers from Imperial College London, Durham University, University of Cambridge, The Chinese University of Hong Kong, Zhejiang University, Beihang University, Nanjing Tech University, Macquarie University, University of British Columbia and Aalto University collaborated to examine the "coffee ring effect" which has been hindering the industrial deployment of functional inks with graphene, 2D materials, and nanoparticles because it makes printed electronic devices behave irregularly.

The team of researchers has now created a new family of inks that overcomes this problem, enabling the fabrication of new electronics such as sensors, light detectors, batteries and solar cells.

Payper to test its graphene-based restaurant payment method

Payper Technologies, UK-based start-up that developed a graphene-based solution, a new pay-at-table technology, has announced that it has secured the first trial site in Manchester, at the five-star Lowry Hotel River restaurant. Using graphene-enhanced receipt paper, the user simply places their phone on the restaurant bill and a payment screen appears on screen in seconds.

Targeting restaurant owners wanting to refine the checkout process, Payper's five-second payment method uses graphene's unique properties in its printed electronics, which enable the mobile phone to detect and display the receipt data using native NFC functionality. An option to pay will then appear on-screen, allowing customers to make the payment in two clicks, without waiting for staff or needing to download an app.

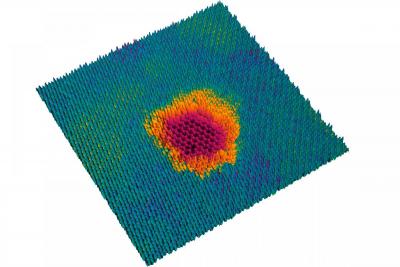

New machine-learning method could characterize graphene materials quickly and efficiently

Monash University scientists created an innovative method to help industry identify high quality graphene cheaper, faster and more accurately than current methods. The researchers used the data set of an optical microscope to develop a machine-learning algorithm that can characterize graphene properties and quality, without bias, within 14 minutes.

This technology could be a game changer for hundreds of graphene or graphene oxide manufacturers globally. It will help them boost the quality and reliability of their graphene supply without need for time-consuming procedures.

Currently, manufacturers can only detect the quality and properties of graphene used in a product after it has been manufactured. Through this algorithm, which has the potential to be rolled out globally with commercial support, graphene producers can be assured of quality product and remove the time-intensive and costly process of a series of characterization techniques to identify graphene properties, such as the thickness and size of the atomic layers.

Huawei's MatePad is the first 5G tablet with graphene heat dissipation technology

Huawei continues the use of graphene heat dissipation technology, which started with the use of graphene film in Huawei Mate 20X and continues with later versions, with its Huawei MatePad Pro 5G launched earlier in 2020. The MatePad is a 5G tablet, equipped with ultra-thick 3D graphene heat dissipation technology.

For this technology, graphene is used as raw material, in the form of oriented thermal conductive films embedded in several layers of graphene with good mechanical properties, high thermal conductivity, lightweight, thin material, and high flexibility.

Researchers develop enhanced graphene sieve that could advance clean water efforts

Vanderbilt engineers designed a simple defect-sealing technique to correct variations in pore size in graphene membranes. The researchers reported a breakthrough in scalable fabrication of graphene membranes with a sealing technology that corrects variations in the pore size so they remain small enough to trap salt ions and small molecules but allow water to pass.

The team members designed a simple defect-sealing technique based on a gatekeeper analogy. While most prior studies formed holes in graphene membranes as a final step, this team turned the process around. They formed holes in the graphene first using a low-temperature chemical vapor deposition (CVD) process followed by ultraviolet light in the presence of ozone gas and used the size of the holes as a gatekeeper. A sealant molecule on one side has to pass through the gate to meet another molecule on the other side and form a seal. If the size of the molecule is smaller than the gate, it will pass through, meet the other molecule and seal the gate. If the size of the molecule is larger than the gate, it will not pass and the gate will remain open.

The graphene membrane can separate 0.28 nanometer (water) from 0.66 nanometer (hydrated salt ions) via a simple size-selective defect sealing technique. For comparison, one inch is equal to 25,400,000 nanometers. The researchers used table salt (NaCl) and potassium chloride (KCl), a salt that occurs naturally seawater or underground brackish water, as well as the amino acid L-tryptophan and the water-soluble vitamin B-12 in their experiments.

India-based clean-tech startup Log 9 has supplied graphene-enhanced oil absorbent pads 'Sorbene' to clean up a major oil spill off the coast of Mauritius.

Flextrapower (formerly Bonbouton) has been developing several graphene-based applications, including the most recent COVID-focused effort, a graphene mask.

Versarien announced the launch of its first graphene-enhanced protective face mask, which utilizes Polygrene, Versarien’s graphene-enhanced polymer.

G6 Materials, formerly known as Graphene 3d Lab, announced finalizing the research and development project to develop graphene-based composite materials for marine vessel applications with a private Singaporean company.

Archer Materials progressed its graphene-based biosensor technology development by successfully prototyping key device hardware using additive manufacturing (3D printing).

Graphene buckles when cooled while attached to a flat surface, resulting in patterns that could benefit the search for novel quantum materials and superconductors, according to a recent Rutgers-led research.

Physicists at the University of Basel have created a novel structure with the ability to absorb almost all light of a selected wavelength, by layering different 2D materials: graphene and molybdenum disulfide.

Chinese researchers developed a new preparation method for hybrid graphene composites by introducing new electrochemical techniques, according to the Chinese Academy of Sciences (CAS).

Directa Plus signed a technical and commercial agreement with automotive design and engineering firm Italdesign.

Researchers from the Centre for Nano and Soft Matter Sciences (CeNS) developed a novel palladium and rGO based electrocatalyst for hydrogen production that exhibits high catalytic efficiency with a low overpotential and high durability.

Researchers at the Fraunhofer Institute for Reliability and Microintegration IZM have joined forces with partners in industry and healthcare to develop a graphene oxide based sensor platform to detect acute infections such as sepsis or the antibodies against the coronavirus within minutes.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!