The Graphene-Info newsletter, April 2019

Published: Tue, 04/02/19

Novel graphene film offers new concept for solar energy

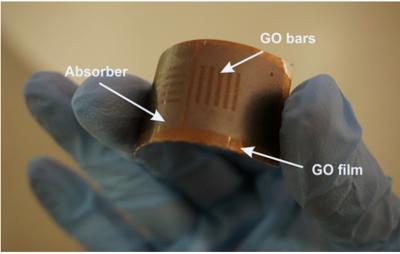

Researchers at Swinburne, the University of Sydney and Australian National University have collaborated to develop a solar absorbing, ultra-thin graphene-based film with unique properties that has great potential for use in solar thermal energy harvesting.

The 90 nanometre material is said to be a 1000 times finer than a human hair and is able to rapidly heat up to 160°C under natural sunlight in an open environment. The researchers have developed a 2.5cm x 5cm working prototype to demonstrate the photo-thermal performance of the graphene-based metamaterial absorber. They have also proposed a scalable manufacturing strategy to fabricate the proposed graphene-based absorber at low cost.

Mitsubishi develops MWIR and LWIR graphene-based sensors

Mitsubishi has reportedly developed graphene-based MWIR sensors with extraordinarily high sensitivity. Thanks to an internal graphene FET gain, the responsivity is said to be 10 times higher than that of quantum-type IR sensors with no internal amplification. Mitsubishi uses graphene FET and leverages its high electron mobility.

Other than a graphene-based FET, reports suggest that there is "a light-amplifying part" that produces photoelectrons and photoholes and is placed under the graphene. At a very low temperature of, for example, 80K, the responsivity increases even more, by a factor of 100x.

Mitsubishi is also reportedly developing LWIR sensors using a dielectric for the light-amplifying. Existing quantum-type LWIR sensors reduce thermal noise by cooling down to liquid nitrogen temperature. Mitsubishi claims that with its new method, the sensor might be able to work at room temperature.

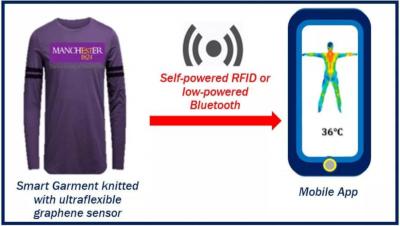

Graphene-based yarn to enable advanced wearable e-textiles

Researchers at the National Graphene Institute (NGI) have created a method to produce scalable graphene-based yarn. Such e-textiles may have great potential for sportswear, healthcare, aerospace, and fitness applications, and so are attracting research attention worldwide.

Integrating textile-based sensors into garments in the manufacturing process is still time-consuming and complex. It is also expensive, non-biodegradable, unstable, metallic conductive materials that are still being used. Now, the NGI researchers have developed a process that has the potential to produce tonnes of conductive graphene-based yarn. It is possible to do this using current textile machinery without any addition to production costs. The produces graphene-based yarn is also said to be flexible, cheap, biodegradable, and washable.

Graphene Composites exceeds crowdfunding target for graphene bulletproof shields

Graphene Composites (GC), a UK-based company developing graphene-enhanced bulletproof shields, has exceeded its crowdfunding target. GC attempted to raise £300,000 on Crowdcube, but ended up raising £510,680 (around 676,625 USD).

Graphene Composites is now looking to expand its business overseas and plans to sell its protection equipment to schools. It believes it can sell a pack of 10 GC Shields for $16,000 and a full school package for around $1 million. The product can reportedly stop both low caliber bullets and high caliber rounds fired from an AR-15 assault rifle and a sniper rifle.

The firm is also designing a Lightning Harvester which can capture static electricity in thunderstorms and feed it into the National Grid as a renewable source of energy.

ECD Lacrosse and Global Graphene Group (G3) develop graphene-enhanced Lacrosse gear

ECD Lacrosse, manufacturer of high quality lacrosse equipment, has teamed up with Global Graphene Group (G3) to develop ECD's Rebel +Graphene heads, which were released in a limited edition.

The customized composite of G3’s graphene with ECD’s polymer reportedly benefits from graphene's properties, including its light weight and impact resistance. The resulting Rebel +Graphene lacrosse heads exhibit increased impact strength, increased stiffness, and no perceptible additional weight.

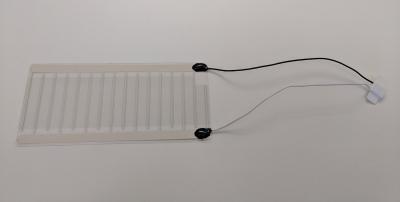

Graphene-Info’s hands-on review of Wuxi Graphene Film's CVD graphene heating films

China-based Wuxi Graphene Film (owned by Grahope New Materials and The Sixth Element) produces patterned CVD graphene films for heating applications, which are adopted by several Chinese device makers for different heating products. The team at Wuxi Graphene Film was kind enough to send a few such films for us to review. These specific films are designed for one of WGF's customers and include a proprietary design with a USB connector for easy setup - you just plug these into a USB power source and the films heat up very quickly.

The films are plastic films, covered with a patterned metal coating (this is the silver-gold pattern easily seen on the films). The pattern itself is done according to customer’s needs. The metal pattern is the main conductor of electricity on the film. The film is also coated with a single-layer CVD graphene sheet. The graphene is of course highly transparent (it allows around 97% of the light to go through) - but if you hold the film up to a light source, you can see where the graphene coating ends. The high thermal conductivity of the graphene transfers the heat to the air in a uniform method.

Researchers from Jagiellonian University in Poland, Oak Ridge National Laboratory in the U.S, Espeem S.A.R.L in Luxembourg and Friedrich Alexander University(FAU) in Germany have designed a method of forming nanographenes on metal oxide surfaces.

Researchers from the Chinese Tsinghua University and CAS demonstrated a coupled photon-electron-ion transport phenomenon through graphene oxide membranes.

Researchers in India have made graphene field-effect transistors based on discrete inorganic structures that reportedly work for over 10 months.

Researchers at MIT have utilized an everyday material - wax- to protect graphene from performance-impairing wrinkles and contaminants.

University of Cambridge spin-out company, Paragraf, recently announced that it started producing graphene at up to eight inches (20cm) in diameter, large enough for commercial electronic devices.

A technology developed by a team at the Nanomol Group at ICMAB, has been selected as a high potential innovation by the European Union (EU).

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!