The Graphene-Info Newsletter, March 2019

Published: Tue, 03/05/19

LifeSaver and NGI to collaborate on graphene-enhanced water filtration system

LifeSaver, a UK-based manufacturer of portable and reusable water filtration systems, announced an exclusive contract with the National Graphene Institute (NGI) at The University of Manchester.

The 18-month research project will focus on developing graphene technology that can be used for enhanced water filtration, with the goal of creating a proprietary and patented, cutting-edge product capable of eliminating an even wider range of hazardous contaminants than currently removed by its existing high-performance ultra-filtration process.

Rice and BGU present a range of exciting new graphene-enhanced composite materials

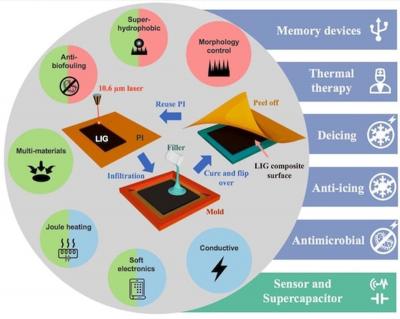

The labs of Rice University chemist James Tour and Christopher Arnusch, a professor at Ben-Gurion University of the Negev in Israel, introduced a batch of graphene-enhanced composites that can be a step towards more robust packages.

By infusing laser-induced graphene with plastic, rubber, cement, wax or other materials, the lab made composites with a wide range of possible applications. These new composites could be used in wearable electronics, in heat therapy, in water treatment, in anti-icing and deicing work, in creating antimicrobial surfaces and even in making resistive random-access memory devices.

Graphene Lighting launches new plant and receives orders

Manchester-based Graphene Lighting announced the commencement of its new wholly owned mass production facility in Shenzen, China. The Company shared that its previous plans of merging with JTX ended in October 2017, and it will focus its efforts towards sales and marketing using its own and partner capabilities. Graphene Lighting also said that the manufacturing facility has been in pilot production for the last 6 months and has commenced product shipment over the last four weeks.

The newly established facility in China manufactures the company’s flagship product, the Graphene Light Bulb, with its unique patented curved filament and heat dissipation technology. It also serves as the company’s research and development center, as it further develops intellectual property. Going forward the Company is in discussions with an established and leading light bulb manufacturer with a 20-year-old history to produce the Graphene Lighting product range on an OEM basis.

CPI, Haydale and others collaborate on Smart Filter project

The Centre for Process Innovation (CPI) has collaborated on a project to advance the development of a low-cost, self-cleaning coating technology for industrial filter membranes. The Smart Filter project used graphene and its derivatives to create a coated filter membrane that offers increased resistance to fouling for industrial waste water treatment.

Membrane filters are used in a number of industrial separation applications but are afflicted by fouling, which typically lowers throughput or increases energy consumption, and reduces filter life. Focusing upon oil water separation and nuclear waste water treatment, the collaboration, with G2O Water Technologies, Haydale and Sellafield, developed a repeatable, reproducible and scalable process to make coated filter membranes, which delivered a 30% improvement in permeability when compared to an equivalent uncoated filter.

Graphene-enhanced E-skin generates and stores electricity for prosthetic devices

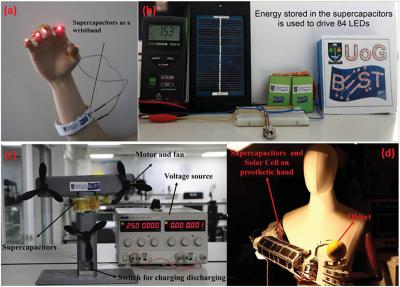

Researchers at the University of Glasgow in Scotland developed an electronic “skin” that can generate and store electricity for prosthetic devices.

The technology consists of layers of a finely tuned graphite-polyurethane composite covered by graphene. The team explained that the graphite-polyurethane works as an electric supercapacitor, storing energy that can be used at any time by a prosthetic. The graphene component is said to essentially be a solar panel that converts sunlight to electricity to charge the supercapacitor. The Glasgow team conducted a series of experiments using their power system, including lighting 84 bright LEDs and running high-torque motors of a prosthetic hand.

The fabricated supercapacitors (SCs) reportedly yielded a stable response for more than 15,000 charging/discharging cycles at current densities of 10 mA cm−2 and operating voltage of 2.5 V. The developed SCs are tested as energy storage devices for wide applications, like solar‐powered energy‐packs to operate 84 light‐emitting diodes (LEDs) for more than a minute and to drive the actuators of a prosthetic limb, for powering high‐torque motors and for wearable sensors.

New test results on the ongoing optimization of Talga’s graphene silicon Li-ion battery anode product, Talnode- Si, reportedly show that the battery anode product returns improved performance gains.

Rice University and Iran University of Science and Technology researchers have found a unique ceramic material that could act as a sensor for structures.

Researchers at the Norwegian University of Science and Technology (NTNU) in Norway, Sophia University in Japan and SINTEF Industry, Norway demonstrated the use of graphene as both a growth substrate and transparent conductive electrode for an ultraviolet light-emitting diode.

First Graphene announced a project with Steel Blue to develop graphene-enhanced safety boot components. Steel Blue is one of Australia’s leading suppliers of safety work boots.

Haydale announced its financial results for H1 FY2019 (six months ended 31 December 2018).

New graphene-enhanced equipment developed in Brazil - the Solar-T - will be sent to the International Space Station (ISS) to measure solar flares.

Graphene Flagship researchers at DTU, Denmark, solved the problem of graphene's accumulation of defects and impurities due to environmental exposure by protecting it with insulating layers of hexagonal boron nitride.

Haydale is working alongside Swansea University, GTS Flexibles, Alliance Labels, Tectonic International, ScreenTec, Alliance Labels, Malvern Panalytical and the English Institute of Sport on a Welsh Government SMART Expertise program for the development of new concepts and advanced functionalized inks using Haydale’s advanced materials.

A new study led by the Ulsan National Institute of Science and Technology in South Korea reveals a technology capable of fabricating highly ordered arrays of graphene quantum dots.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!