The Graphene-Info newsletter, December 2018

Published: Mon, 12/03/18

Australia-China partnership moves into manufacturing phase of graphene cables

The University of New South Wales (UNSW) in Sydney and China's Hangzhou Cables have formalized a major collaboration to begin large-scale manufacturing of graphene power cables, which promise to cut electricity costs and improve grid transmission. This is an advancement of the May 2016 engagement between the two.The agreement will move the project into the second stage of development.

An initial 10-meter prototype of the cable technology, developed at the Kensington campus over the past two years, showed that graphene can be used to stop electricity leakage that happens with conventional power cable and grids, which could deliver significant savings in electricity and emissions. The project is a flagship collaboration of the Torch Innovation Precinct at UNSW – an unprecedented partnership between UNSW-led research teams and Chinese businesses and industries with the capital and market access needed to translate Australian research into high-impact new products, processes and services.

Bionic mushroom interacts with bacteria and graphene to generate electricity

In a recent study, researchers from the Stevens Institute of Technology in the U.S came up with an original idea - they designed a ‘bionic mushroom’ that uses graphene to produce electricity. More accurately, the researchers have generated mushrooms patterned with energy-producing bacteria and an electrode network.

The research team wanted to engineer an artificial symbiosis between button mushrooms and cyanobacteria. In their vision, the mushroom would provide shelter, moisture and nutrients, while bacteria 3D-printed on the mushroom's cap would supply energy by photosynthesis. Graphene nanoribbons printed alongside the bacteria could capture electrons released by the microbes during photosynthesis, producing bio-electricity.

To develop their bionic mushroom, the researchers first 3D printed an electronic ink containing graphene nanoribbons onto the cap of a living mushroom in a branched pattern. They then printed a bio-ink containing cyanobacteria onto the cap in a spiral pattern, which intersected with the electronic ink at multiple points. At these sites, electrons could transfer through the outer membranes of the bacteria to the conductive network of graphene nanoribbons. Shining a light on the mushroom activated cyanobacterial photosynthesis, generating a current of about 65 nanoAmps. Although this current is insufficient to power an electronic device, the researchers say that an array of bionic mushrooms could generate enough current to light up an LED. The researchers are now working on ways to generate higher currents using this system.

Leiden researchers visualize how atoms behave in between graphene and a substrate

Researchers from Leiden University in the Netherlands have visualized how atoms behave in between graphene and a substrate, which could be instrumental for future implementations of industrial graphene production.

A basic idea for large-scale production is heating silicon carbide to almost 2,000 degrees C, and a graphene layer grows on its surface. However, researchers need to make sure that the desired properties of the graphene are not disturbed by the substrate. Inserting hydrogen atoms in between the graphene and silicon carbide isolates the graphene and leaves it intact as a single-layer material. Physicist Sense Jan van der Molen and his research group at Leiden University have visualized for the first time how those atoms behave underneath the graphene. The researchers used a low-energy electron microscope (LEEM) to study what happens to hydrogen atoms sandwiched between graphene and silicon carbide.

Hands-on review: Grahope's graphene eye mask

Grahope New Materials (GNM), China-based developer of graphene applications with a special focus on heating applications, has commercialized and is selling several types of graphene-based products, ranging from home textiles and clothes to therapeutic products. We have experimented with the Company’s graphene eye mask and following are our results.

The Company states on its website that the mask "effectively soothes the eyes and alleviates eye fatigue", by heating rapidly and generating "far infra-red waves that are similar to the human body's". This is quite hard to prove or disprove, but there are some things that we can say about the mask. It came neatly packaged in a sleek black box engraved with silver letters and logo. The mask itself is lightweight, made of a soft, pleasant fabric and feels rather good when placed on the eyes. It blocks light quite perfectly, and really does heat up fast. As an initial assessment, the whole product has a nice, quality feel to it. Read the full post to hear the rest of our review.

Graphene to enable next-gen reflective-type displays that operate faster and at much higher resolution than currently possible

A joint collaboration of researchers from SCALE Nanotech, Graphenea and TU Delft have used graphene to make reflective-type displays that operate faster and at much higher resolution than existing technologies.

Displays consume the most power in electronic gadgets. Portable devices like smartphones and VR visors therefore require most of the energy from batteries. As an alternative solution, reflective-type displays (like those in e-book readers) consume much less power, though they cannot deliver video. Reflective displays that offer the specifications of standard technologies (OLED, LCD) do not exist yet, but graphene may open the door to such possibilities.

The team explained that graphene is the thinnest, strongest material and the best electrical conductor, which is an ideal combination for micro-electromechanical systems (MEMS). Membranes in a graphene MEMS can be moved by applying an electric potential and, together with the large optical absorption of graphene (2.3% of visible light), the researchers used them to make a Graphene Interferometric MOdulator Display or simply GIMOD. Read the full post to learn about the rest of the team’s work.

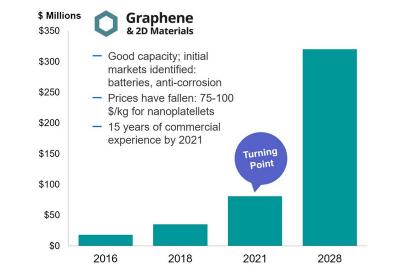

IDTechEx: 2021 will be the turning point in the graphene industry, graphene sales will reach almost $350 million by 2028

IDTechEx says that while graphene is still recovering from its hype curve, commercialization is making steady progress, with increased industry experience, availability - and volume sales.

IDTecEx says that the market "inflection point" is expected to happen in 2021 - by then the industry will have an experience of over 15 years and sales volume will reach almost $100 million.

By 2028, graphene revenues will reach almost $350 million. It is important to remember that graphene is an additive material, mostly, and so even small volumes may enable a large amount of materials and applications. In addition prices are expected to continue their fast decline.

A new guide to promising perovskite materials: The Perovskite Handbook

The Graphene-Info team takes pleasure in recommending our new book - The Perovskite Handbook. While not focused on graphene, we believe that any person interested in advanced materials and emerging technologies would find that perovskite materials are an area of focus that should not be ignored.

This book gives a comprehensive introduction to perovskite materials, applications and industry. Perovskites offer a myriad of exciting properties and are considered the future of solar cells, displays, sensors, lasers and more. The promising perovskite industry is currently at a tipping point and on the verge of mass adoption and commercialization.

The graphene industry should especially pay attention to perovskites as much work is done on combining these two material technologies to create better solar cells, displays and more.

A KAIST research team has developed a graphene-based hybrid storage device with power density 100 times faster than conventional batteries, allowing it to be charged within a few seconds.

Graphene Leaders Canada launched its GLC+ Water Technologies Platform, which according to the Company "offers a solution to water pollution and remediation and is based on years of expertise in graphene solutions work with a keen focus in water filtration".

Researchers at Brown University, the University of Wisconsin and the National University of Singapore developed a way of reinforcing hydrogel materials made from alginate, a natural material derived from seaweeds that’s currently used in a variety of biomedical applications, by incorporating graphene oxide into its structure.

The Materials+ Technology research group at the UPV/EHU’s Faculty of Engineering, in collaboration with the University of Strasbourg, developed unique hydrogels with potential biomedical applications.

Haydale announced that through its Taiwanese operation, Haydale Technologies Taiwan, it started to supply commercial quantities of its functionalized graphene ink to a major print house in Taiwan. The graphene ink is used to print test strips in the self-diagnostic biomedical sensor device market for diabetes monitoring.

Haydale announced the signing of an exclusive license agreement between Haydale Technologies (Thailand) and TKS Siampress Management to use the patented anti-counterfeiting technology ("PATit") in commercial applications on an exclusive basis in Thailand and one other territory to be decided by the parties.

Researches from the University of California, Riverside and University of California, Los Angeles have demonstrated a novel above-IC graphene NEMS switches for electrostatic discharge (ESD) protection applications.

Scientists from the Center for Nano Energy Materials (CNEM) of Northwestern Polytechnical University in China said they have successfully applied graphene‐enhanced nano-materials to protect ancient wall paintings.

Graphenea recently launched a graphene foundry service – GFAB. The company will manufacture custom circuit designs on graphene wafers up to 6”.

Researchers from the Foundation of Research and Technology-Hellas, Patras, Greece and Aristotle University of Thessaloniki, Greece have developed a technique for creating nanopores in CVD grown graphene. The technique is based on femtosecond (fs) laser treatment of graphene.

Versarien announced that it entered into a Memorandum of Understanding with Jinan High-tech Financial Investment ("JHFI") in connection with the Company's ongoing plans to establish a manufacturing center in the Jinan Innovation Zone, Shandong Province, China

Australia-based advanced materials technology company, Talga Resources, reported outstanding conductivity results from its Talphene-enhanced epoxy composite trials undertaken at TWI in the UK.

Ionic Industries signed an LOI with US-based Nanothings for development of graphene supercapacitors for IoT applications.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!