The Graphene-Info newsletter, November 2017

Published: Mon, 12/04/17

Graphene-enhanced anti-corrosion system deployed in bridges and wind power towers across China

China-based The Sixth Element Materials launched its graphene-zinc anti-corrosion primer back in 2015 together with his partner Toppen Technology, and the company has since performed extensive testing. TSE updates us that the material has now been deployed in China and has been used to cover several bridges and wind-turbines steel towers.

The Sixth Element graphene type SE1132 is added to Toppens 2k-epoxy primer system. TSE says that by adding 1% of graphene, one could reduce the zinc content in current anti-corrosion coatings from ~80% to 25%, and the the corrosion protection time is doubled. Reducing the zinc also means that this solution is less polluting. The main cost savings comes from the prolonged coating life which means that the time between coating renewal (which requires a lot of labor) is doubled.

Samsung's "graphene balls" improve the performance and charging time of Li-ion batteries

Samsung announced the development of a unique "graphene ball" that could make lithium-ion batteries last longer and charge faster. In fact, Samsung Advanced Institute of Technology (SAIT) said that using the new graphene ball material to make batteries will increase their capacity by 45% and make their charging speed five times faster. It was also said that batteries that use graphene ball can maintain a temperature of 60 degrees Celsius that is required for use in electric cars.

SAIT's team used a chemical vapor deposition process to grow a graphene–silica assembly, called a graphene ball. Each graphene ball is composed of a SiOx nanoparticle center and surrounding graphene layers, constituting a 3D popcorn-like structure. The graphene-ball coating improves cycle life and fast charging capability by suppressing detrimental side reactions and providing efficient conductive pathways.

The graphene ball itself also serves as an anode material with a high specific capacity of 716.2 mAh g−1. A full-cell incorporating graphene balls increases the volumetric energy density by 27.6% compared to a control cell without graphene balls, showing the possibility of achieving 800 Wh L−1 in a commercial cell setting, along with a high cyclability of 78.6% capacity retention after 500 cycles at 5C and 60 °C. Samsung has patented the technology in South Korea and the US.

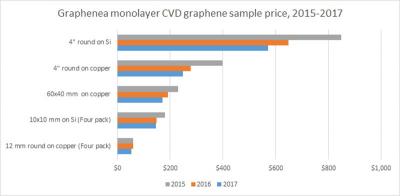

CVD Graphene prices continue to drop as commercial applications start to enter the market

CVD processes are used to create high-quality single layer (also bi-layer and tri-layer) graphene sheets. These kinds of sheets exhibit exceptional properties and can be used in a variety of exciting applications, from touch layers to transistors and sensors. For many years, CVD has been a high cost production process and this graphene is still mostly used in research projects in academic and research institutes, but prices are gradually dropping, to the point where commercial applications are starting to appear on the market.

CVD graphene is still too expensive for many applications, but the price trend is encouraging. Apart from Graphenea’s figures, shown in the graph above, other examples are starting to appear. China's Wuxi Graphene Film, for instance, is producing touch sensors based on graphene, and in Europe we are seeing initial products such UV LEDs, bio-sensors and photodetectors. Graphenea even says that the current price of graphene is lower than some other materials used in the electronics industry - such as GaN.

Graphene's internal motion could provide limitless clean energy

Researchers at the University of Arkansas, led by professor Paul Thibado, have found strong evidence that the internal motion of 2D materials could be used as a source of clean, limitless energy. The team has reportedly taken the first steps toward creating a device that can turn this energy into electricity, with the potential for many applications. A patent has recently been applied on this invention, called a Vibration Energy Harvester, or VEH.

Such a VEH device would involve a negatively charged sheet of graphene suspended between two metal electrodes. When the graphene flips up, it induces a positive charge in the top electrode, and when it flips down, it charges the bottom one, creating an alternating current. A VEH technology could have significant implications on the effort to connect physical objects to the digital world. This self-charging, microscopic power source could make everyday objects into smart devices, as well as powering more sophisticated biomedical devices such as pace-makers, hearing aids, and wearable sensors.

The Zolo graphene-enhanced wireless earphones are now commercially available

Earlier this year, Anker’s audio brand, Zolo, launched a Kickstarter campaign for its Liberty+, a pair of graphene-enhanced fully wireless earphones. The Zolo Liberty earphones (not yet the Liberty+, which will have double the battery life) have been launched, and are now available on Amazon.

The earphones cost $99, which may seem expensive but the company explains that these are already wireless and offer a whole-day battery life. It also comes with AI for smart assistance and is sweat-proof (and so suitable for use in fitness activities). The ZOLO promises super clear and immersive sound quality and the graphene-enhanced technology reportedly results in impressive treble and clarity.

Indian team produces high surface area graphene from waste peanut shells

Researchers at India's Institute of Nano Science and Technology (INST) developed a new route for the scalable preparation of large area few-layer graphene from waste biomass (nutshells) for high-performance energy storage devices.

The team's objective of using biomass-waste is not only to solve the problem of waste recycling but also to generate value-added materials like conductive graphene for renewable energy storage devices such as supercapacitors. The Peanut shell-derived graphene is said to possess remarkably high specific surface area (2070 m2 g−1) and excellent specific capacitance. This method is reportedly scalable, renewable and cost-effective.

IIT and FADEL unveil graphene-enhanced shoes

Graphene Flagship partners Istituto Italiano di Tecnologia, Italy, in collaboration with FADEL, a leading Italian shoe company, developed graphene-enhanced shoes. The new GET technology, patented by FADEL, reportedly gives the footwear better thermoregulation and freshness.

In this innovative shoe, when flakes consisting of several graphene layers are added to polyurethane, (the material of which the soles of FADEL shoes are made), laboratory tests show an augmented heat dispersion, a greater resistivity to water and enhanced antibacterial properties. Combining these effects with a ventilation system developed for this particular type of shoe yielded a better user experience. This prototype shoe was presented at the International Footwear Exhibition in Milan

Urbix launches graphene-based supercapacitors

U.S-based Urbix Resources unveiled new high-density, low leakage graphene-based supercapacitors. According to Urbix, these supercapacitors have energy density of >75 wH/L with volumetric discharge energy density that is five times larger than average, with the lowest leakage rate in market (<1μA/day over 30 days) and operational temperatures that go from -40° C to 70°C.

The supercapacitors can be customized to meet customer specifications, and can be included in other proprietary Urbix Energy Storage Systems upon request. According to Urbix, the products come in 3 form factors: 2032 (with capacitance of 2.5F), 2430 (4F capacitance) and custom (with custom capacitance).

A team of TU Delft researchers found that graphene sheets may be used as light sails for spacecraft.

Sweden-based 2D Fab AB will join SAAB and Blackwing Sweden in developing new graphene-based components to the aviation industry.

Haydale, ARTIS, part of Avon Rubber and Trelleborg Antivibration Solutions announced a two-year R&D project to investigate the use of Haydale’s plasma functionalization for the enhancement of recovered carbon materials that are produced from the recycling of waste tyres.

The NGI joined forces with the NPL to develop a guide, as part of NPL's good practice guide series, that conveys "a detailed description of how to determine the key structural properties of graphene, so that the graphene community can adopt a common metrological approach that allows the comparison of commercially available graphene materials.”

PPG, longtime developer of paints, coatings and other materials, announced it has entered into a partnership with SiNode Systems to accelerate the commercialization of high-energy anode materials for advanced battery applications in electric vehicles.

Directa Plus announced its collaboration with Iterchimica to develop a graphene-enhanced asphalt additive, which is patent-pending, that can significantly improve the durability and sustainability of asphalt road surfaces.

Chemicals manufacturer Thomas Swan announced an expansion of its range of formulated Elicarb Graphene materials with a prototype product focusing on the manufacture of a carbon fiber composite prototype.

The NGI at The University of Manchester and William Blythe have announced the start of a new joint research project, targeting the development of high capacity graphene-related materials for use in the electric vehicle market.

Xefro, the UK-based company that reported developing a graphene-based heating system in 2015, was wound-up (liquidated) by the High Court after determining that it sold its products on the basis of misrepresentations and an investigation found the company misled the public and failed to install systems safely.

Researchers from Cambridge University demonstrated how graphene and other related 2D materials (namely hBN) can be directly printed onto textiles to create fully inkjet-printed dielectrically gated field effect transistors (FETs) with solution processed 2D materials.

Researchers at the National Graphene Institute and The University of Manchester developed a new form of graphene oxide membrane that can filter organic solvents.

Teams from the University of York and Roma Tre University state showed that ultra-low-power transistors could be built using composite materials based on single layers of graphene and transition metal dichalcogenides (TMDC).

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!