The Graphene-Info newsletter, May 2017

Published: Thu, 06/01/17

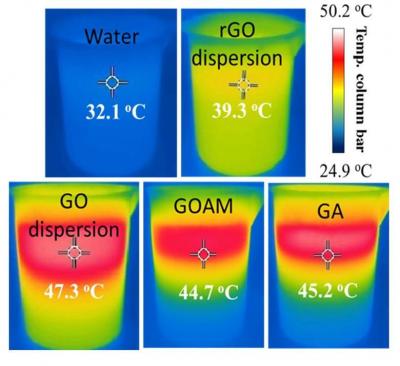

Graphene aerogel used to convert sunlight into heat to produce water vapor at room temperature

Researchers at the Chinese Hubei University have designed a graphene aerogel film capable of producing water vapor at room temperature using only sunlight. The aerogel floats on the surface, where it heats up only a small part of the water column, ‘while the temperature of the bulk water is far below the boiling point’, the team explains.

This sunlight-harvesting graphene film could convert sea or wastewater into drinking water in places where fuel or access to electricity is limited. While other steam-generating materials are based on expensive raw materials such as gold, the basis for this aerogel is a much cheaper resource.

Generating solar steam with the graphene aerogel could be more efficient than using electricity from a photovoltaic cell. ‘The efficiencies of commercial photovoltaic cells are 10–20%, such that the efficiencies of generating steam using photovoltaic cells cannot exceed 20%,’ explain the researchers. This floating graphene has an efficiency of 54%, reaching up to 83% under focused sunlight.

Six things to keep in mind before launching your graphene project

Graphene has become a well-known material, and its remarkable properties are attracting many R&D efforts across all sorts of applications and industries. But despite graphene's massive potential, bringing it out of the lab and into real-world products is not without its challenges, and there are quite a few things to be aware of when attempting to make such a move.

This original article by Graphene-Info will touch upon the major issues one should take into account when considering the use of graphene in any form of product. It is the result of repeated interactions with researchers and companies working on graphene applications. Among the topics mentioned in this article are the theory-lab-industry route (or unrealistic expectations), choosing the right supplier, various costs and storage issues, and more.

Rice U team demonstrates a graphene-CNTs hybrid that could give Lithium batteries a major boost

Researchers at Rice University have created a rechargeable Li-ion battery, based on a hybrid of graphene and carbon nanotubes, with three times the capacity of commercial lithium-ion batteries. This was achieved mainly by addressing a major challenge known as the dendrite problem. Dendrites are lithium deposits that grow into the battery's electrolyte. If they bridge the anode and cathode and create a short circuit, the battery may fail, catch fire or even explode. This issue has sabotaged many attempts to replace lithium-ion with advanced lithium metal batteries that last longer and charge faster.

The Rice battery stores lithium in a unique anode made of a seamless hybrid of graphene and carbon nanotubes. The material (first created at Rice in 2012) is basically a 3D carbon surface that provides abundant area for lithium to occupy. The anode itself is said to approach the theoretical maximum for storage of lithium metal with its 3,351 milliamp hours per gram capacity, while resisting the formation of damaging dendrites or "mossy" deposits.

Zap&Go awarded with $1.6 million from the EU to continue development of its graphene supercapacitor enhanced power tools

UK-based graphene supercapacitor developer Zap&Go announced that it was awarded with a $1.6 million USD from the European Union to perfect the prototype cordless tools powered by its fast-charging graphene supercapacitors.

Zap&Go initiated a self-funded feasibility study to embed its graphene supercapacitors in cordless tools. The company says that it has received commitments from major OEMs in joint development agreements. In this new EU-funded project, Zap&Go intends to further develop its power modules and electronics, integrating them with cordless tools such as vacuum cleaners and power drills, and finally build units to conduct customer trials.

Will graphene help with NASA's mission to get close to the sun?

NASA has announced its first mission to fly directly into the sun’s atmosphere. The mission, Solar Probe Plus, is scheduled to launch in the summer of 2018. Placed in orbit within four million miles of the sun’s surface, facing heat and radiation unlike any spacecraft in history, the vessel will explore the sun’s outer atmosphere and make observations that may answer questions that have long since plagued researchers.

While exciting and scientifically valuable, a mission to get this close to the sun inherently raises the question of thermal management - as the probe will have to endure temperatures up to 1,400° Celsius (about 2,550° Fahrenheit) while keeping its payload at a much lower temperature. Heat shields will no doubt be of massive importance here, and carbon composites will likely be used. It will be interesting to see exactly what kind of these will be chosen; materials like graphene, carbon nanotubes, and several other types of carbon have shown in the past to make for light and durable composites, with interesting thermal properties.

Graphene and quantum dots enable a unique CMOS-integrated camera

Researchers from the ICFO have developed the first graphene-QDs-CMOS integrated camera, capable of imaging visible and infrared light at the same time. The camera may be useful for many applications like night vision, food inspection, fire control, vision under extreme weather conditions, and more.

The imaging system is said to be based on the first monolithic integration of graphene and quantum dot photodetectors, with a CMOS (complementary metal-oxide semiconductors) read-out integrated circuit. The implementation of such a platform in applications other than microcircuits and visible light cameras has been impeded by the difficulty to combine semiconductors other than silicon with CMOS, an obstacle that has been overcome in this work.

The ICFO researchers have shown the monolithic integration of a CMOS integrated circuit with graphene, resulting in a high-resolution image sensor consisting of hundreds of thousands of photodetectors based on graphene and quantum dots (QDs). They operated it as a digital camera that is highly sensitive to UV, visible and infrared light at the same time. According to the team, this has never been achieved before with existing imaging sensors. This demonstration of monolithic integration of graphene with CMOS may open the door to a wide range of optoelectronic applications, such as low-power optical data communications and compact and ultra sensitive sensing systems.

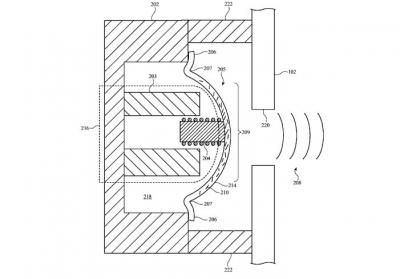

Apple wants to use graphene membranes to enhance next-gen iPhone speakers or microphones

Apple was granted a new patent (filed in 2015) that details an audio device that uses a diaphragm made from a graphene-enhanced composite material. Apple's graphene membrane can be used in a speaker, microphone or headphone device. The patent specifically includes an image of an iPhone device as an example application.

Apple explains that as devices become smaller and lighter, it is ever more challenging to provide high quality audio using conventional materials - and graphene may improve the mechanical response of the audio device. In addition, in some cases, the use of graphene or graphene flake materials may reduce or eliminate the need for additional external damping.

IBM recently announced that its researchers have identified a new way to trigger the body's immune response by using polymer-coated graphene sheets.

Researchers at Rice University and Ben-Gurion University of the Negev in Israel (BGU) have shown that laser-induced graphene LIG (that was invented at Rice) is a highly effective anti-fouling and anti-biofouling material (that protects surfaces from the buildup of microorganisms, plants or other biological material on wet surfaces), and, when electrified, also serves as a bacteria zapper.

MIT researchers have found that a flake of graphene, when brought in close proximity with two superconducting materials, can "borrow" some of those materials' superconducting qualities.

Zenyatta Ventures has announced that the next phase to test a graphene-enhanced concrete admixture is progressing through their Collaboration Agreement with Larisplast, an Israeli business that specializes in the field of concrete admixtures.

Talga Resources recently announced impressive initial concrete prototype strength results from trials undertaken at the commercial concrete/cement laboratory of Betotech Baustofflabor in Germany.

Haydale Graphene Industries recently stated that it has entered a memorandum of understanding with Nanospan India to collaborate on developing advanced nano composites for the Indian market.

Applied Graphene Materials has outlined details of a new graphene-enhanced ink technology and signed a development deal with the University of Sheffield Advanced Manufacturing Research Center.

Rutgers University scientists have created a graphene-based sensor that could lead to earlier detection of asthma attacks and improve the management respiratory diseases, possibly preventing hospitalizations and deaths.

A collaborative project, supported by the UK’s Newton Fund and led by BIOVICI, will bring together the National Physical Laboratory (NPL), the University of Chongqing in China, Swansea University and industry partner CTN, to develop an innovative graphene-based sensor.

Researchers affiliated with UNIST have raised the possibility of in-situ human health monitoring by wearing a contact lens with built-in wireless smart sensors. The team made use of smart contact lens sensors with electrodes made of graphene sheets and metal nanowires.

Researchers from the University of Manchester recently demonstrated fully scalable prototypes of graphene membranes capable of producing heavy water. This new development could possibly lead to the reduction of CO2 emissions associated with heavy water production by up to a million tonnes each year.

The China-based Shandong Longju New Materials Technology announced that it has completed the installation and commissioning of a pilot biomass graphene production line and has put it into operation.

Researchers from the University of Exeter developed a new chip that combines a thermoacoustics graphene-based speaker, amplifier and graphic equalizer.

Researchers from the University of Hamburg and Graphenea have succeeded in upscaling high-quality graphene devices to the 100-micron scale and beyond.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!