The Graphene-Info newsletter, January 2017

Published: Wed, 02/01/17

MIT team uses graphene to create ultra-strong 3D materials

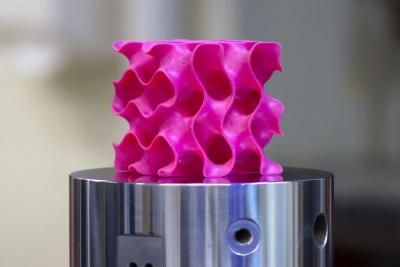

Researchers at MIT have designed a strong and lightweight material, by compressing and fusing flakes of graphene. The new material, a sponge-like configuration with a density of just 5%, can have a strength 10 times that of steel. This work could pose an interesting way of transforming graphene into useful 3D objects and items

The team developed the product by using a combination of both heat and pressure, compressing and fusing the flakes of graphene together. This process produced a strong, stable structure whose form resembles that of some corals and microscopic creatures called diatoms. These shapes, which have an enormous surface area in proportion to their volume, proved to be remarkably strong.

The configurations of their objects were made using 3D printers in the lab, and were then mechanically tested in order to establish their compressive and tensile properties. MIT sees the material someday being used in airplanes, cars, and perhaps even water filtration systems.

Graphene successfully turned into a superconductor

Researchers at the University of Cambridge, managed to activate graphene's potential to superconduct by coupling it with a material called praseodymium cerium copper oxide (PCCO). The researchers suggest that superconductive graphene could have interesting applications; It could be used to create new types of superconducting quantum devices for high-speed computing, and it might also be used to prove the existence of a form of superconductivity known as "p-wave" superconductivity, which academics have been struggling to verify for many years.

Graphene's ability to superconduct has been speculated but thus far has only been achieved by doping it with, or by placing it on, a superconducting material - a process that can compromise some of its other properties. "Placing graphene on a metal can dramatically alter the properties so it is technically no longer behaving as we would expect," the team stated. "What you see is not graphene's intrinsic superconductivity, but simply that of the underlying superconductor being passed on". It remains unclear what type of superconductivity the team activated, but their results indicate that it is the above-mentioned elusive "p-wave" form. If so, the study could transform the ongoing debate about whether this mysterious type of superconductivity exists, and - if so - what exactly it is.

Graphene-based sensor can track vital signs

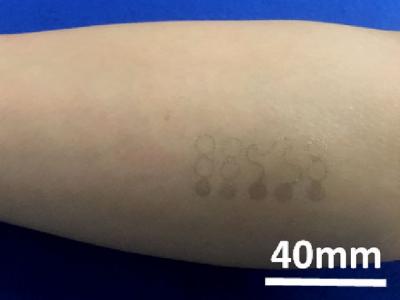

Researchers at the University of Texas have developed a graphene-based health sensor that attaches to the skin like a temporary tattoo and takes measurements with the same precision as bulky medical equipment. The graphene tattoos are said to be the thinnest epidermal electronics ever made. They can measure electrical signals from the heart, muscles, and brain, as well as skin temperature and hydration. The research team hopes to integrate these sensors in applications like consumer cosmetics, in addition to providing a more convenient replacement for existing medical equipment. The sensor takes advantage of graphene's mechanical invisibility - when the sensor goes on the skin, it doesn’t just stay flat—it conforms to the microscale ridges and roughness of the epidermis.

The Texas researchers started by growing single-layer graphene on a sheet of copper. The 2D carbon sheet is then coated with a stretchy support polymer, and the copper is etched off. Next, the polymer-graphene sheet is placed on temporary tattoo paper, the graphene is carved to make electrodes with stretchy spiral-shaped connections between them, and the excess graphene is removed. Then the sensor is ready to be applied by placing it on the skin and wetting the back of the paper.

In their proof-of-concept work, the researchers used the graphene tattoos to take five kinds of measurements, and compared the data with results from conventional sensors. The graphene electrodes were able to pick up changes in electrical resistance caused by electrical activity in the tissue underneath. When worn on the chest, the graphene sensor detected faint fluctuations that were not visible on an EKG taken by an adjacent, conventional electrode. The sensor readouts for electroencephalography (EEG) and electromyography (EMG, which can be used to register electrical signals from muscles and is being incorporated into next-generation prosthetic arms and legs) were also of good quality. The sensors could also measure skin temperature and hydration, which could be useful for cosmetics companies.

Graphene and porphyrins join to create an exciting new material

Researchers at the Technical University of Munich have found that graphene can be combined with porphyrins, the molecules that convey oxygen in haemoglobin and absorb light during photosynthesis, to get a material with exciting new properties. The resulting hybrid structures could be used in the field of molecular electronics, solar cells and in developing new sensors.

The technique involves growing a graphene layer on a surface of silver to use its catalytic properties. Then, under ultra-high vacuum conditions, porphyrin molecules are added. These lose the hydrogen atoms from their periphery when heated on the metal surface, and they end up connecting to the graphene edges. The researchers used an atomic force microscope to characterize the chemical structure of the molecules. With this tool they observed, for example, a metal being incorporated at the centre of the porphyrins, as well as the specific bond of gas molecules, such as carbon dioxide, without altering the graphene properties.

According to the team, this new graphene ‘functionalization’ technique could be extended to more molecules in the future, which would bond to various carbon nanostructures, like graphene nanoribbons, while also having great potential in the development of electronic applications.

New graphene products and prototypes

McLaren, the British racing team/supercar manufacturer, has announced the graphene-enhanced new RM 50-03 Tourbillon Split Seconds Chronograph Ultralight McLaren F1. The watch's mechanism weighs only 7 grams and the entire watch just 40, with the help of a graphene, titanium and carbon fiber composite. Only 75 pieces of this watch will be made, each selling for $1 million. excluding tax.

A graphene dress was showcased in Manchester. The dress came out of a partnership involving wearable tech pioneers Cute Circuit and the National Graphene Institute at the University of Manchester. The dress has a graphene sensor which tracks the model's breathing, and it will change color according to the wearer's breathing rate - glowing purple upon fast breaths while slow and turquoise when breathing slowly. Graphene was used to power the LED lights and in the sensor that records the wearer’s breathing.

Stanford team demonstrates a graphene-based thermal-to-electricity conversion technology

Researchers at Stanford University have recently demonstrated a graphene-based high efficiency thermal-to-electricity conversion technology, called thermionic energy converter. By using graphene as the anode, the efficiency of the device is increased by a factor of 6.7 compared with a traditional tungsten anode. This technology can work in a tandem cycle with existing thermal-based power plants and significantly improve their overall efficiencies.

The current demonstration of the TEC device is done in an ultra-high vacuum chamber, with many pumps constantly pumping down the pressure. In reality, it will be vital to fabricate such a TEC device and seal it in a vacuum ‘chip’ using nano/micro fabrication techniques. Only by making the device small and reliably stable would it be economically feasible in the sustainable energy industry. The team envisions such a TEC device in the future, which is sealed in a small and thin cell (TEC cell). To generate electricity, all you need to do is to attach one side of the cell to a heat source. You may attach a couple of the TEC cells to the water heater at your home to charge your phone. Or attach many TEC cells to a fossil-fuel power station to improve its overall efficiency.

ANM2017: 3rd International conference on Advanced Graphene Materials

ANM2017 (www.anm2017.com) is conference series on nanotechnology that will be held at the University of Aveiro, Portugal, Europe, on July 19-21, 2017, focusing on the below parallel events:

- 9th International conference on Advanced Nanomaterials

- 3rd International conference on Advanced graphene materials

- 2nd International conference on Advanced magnetic and Spintronics materials

- 1st International conference on Advanced polymer materials and Nanocomposites

These international nanotechnology symposiums, which will be hosted simultaneously as parallel sessions, promote the gathering of scientists, students and industry experts to exchange and enhance their knowledge and vanguard ideas for future applications. The topics explored will include and are not limited to: nanomaterials, nanoelectronics, nanoenergy, nanomedicine, nanomechanics, graphene materials, spintronics materials, devices and more. www.anm2017.com

New on Graphene-Info

Graphene-Info’s new article: introduction to graphene quantum dots

Graphene quantum dots are getting a lot of attention lately, as these new materials are entering the market, and as companies rush to find heavy-metal free quantum dots solutions, especially for the display industry. Don't miss our new article that introduces GQDs and reviews the latest activities in this emerging market.

Graphene-Info launches a new Graphene Oxide market report

We're happy to announce a new market report: The Graphene Oxide Market Report, a comprehensive guide to the graphene oxide market. Graphene oxide is an exciting material with promising applications in diverse areas - including energy storage, composite materials, bio-medical, water treatment and more. Graphene oxide can also be reduced to make conductive graphene flakes (r-GO).

Graphene-Info's top 10 graphene applications of 2016

To welcome 2017, the Graphene-Info team would like to wish all of its readers a very happy new year! 2016 has been a busy year for graphene, as the market is shifting from R&D to graphene implementation and commercialization. Click here to discover 2016's top 10 graphene applications, ranked by the number of posts written about them.

The Graphene Handbook, 2017 edition

We're happy to announce the fourth edition of Graphene-Info's very own Graphene Handbook, the most comprehensive resource on graphene technology, industry and market - now updated for 2017. Get your copy now to stay current on graphene research, development and market!

In a recent coatings event held in China, The Sixth Element and Daopeng Technology presented graphene-based anti-corrosion coatings.

The Commonwealth Scientific and Industrial Research Office (CSIRO) has developed a novel method that uses soybean oil and other waste oils to produce graphene. Called ‘GraphAir’, the method is said to make graphene production faster and simpler.

The Fraunhofer Institute FEP and other partners at EU GLADIATOR project developed a functional flexible OLED lighting device based on graphene electrodes. This device is 2 x 1 cm in size - much larger the previous prototype developed as part of that project last year.

In its latest quarterly review, Talga Resources reported interesting highlights such as graphene battery anode testing and work with the IIT on graphene-based sensors.

Future Markets has released a new report titled “The Graphene and 2-D Materials Global Opportunity and Market Forecast 2017-2027 Report”, that predicts that the graphene market will reach $250 million in revenues in 2017.

It was recently announced that work on the Smart Filter project, initially declared in October 2015, has begun. The project aims to develop a low cost self-cleaning coating technology based on functionalized graphene.

Reports from China indicate that new guidelines for industries that create new materials, such as graphene, were published. The guidelines specify that China aims for the stable supply of advanced basic materials by 2020, while making technological breakthroughs in frontier materials, such as graphene and nanophase materials.

Dotz Nano, a nanotechnology company focused on the development, manufacture and commercialization of graphene quantum dots (GQDs), has signed a marketing agreement with Strem Chemicals, a manufacturer and distributor of specialty chemicals headquartered in the U.S.

Polish chemical company Grupa Azoty reportedly plans to invest around €1.4 million in a graphene production line this year. The line is to be located at the group’s plant in Tarnow, Poland, and will have an output capacity of around 1 kg of graphene per week.

Researchers at the University of Illinois and the University of Nebraska-Lincoln have used graphene nanoribbons (GNRs) to create the electronic components used to carry out logic operations in computing. The team described this as "the first step toward integrating atomically precise graphene nanoribbons onto nonmetallic substrates".

Saint Jean Carbon recently announced that it has started the design and build of a graphene based lithium-ion battery.

Researchers from the Lodz University of Technology in Poland have designed a transparent, flexible cryogenic temperature sensor with graphene structures as sensing elements. Such sensors could be useful for any field that requires operating in low-temperatures, such as medical diagnostics, space exploration and aviation, processing and storage of food and scientific research.

Researchers at Rice University have found that it may be possible to make graphene-carbon nanotube junctions excel at transferring heat, turning these into an attractive way to channel damaging heat away from next-generation nano-electronics.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!