The Graphene-Info newsletter, February 2016

Published: Wed, 03/02/16

Impressions from the Mobile World Congress

Last week Barcelona hosted the Mobile World Congress trade show, which was a very large and impressive conference - with over 100,000 visitors and thousands of exhibiting companies. This year the MWC included a graphene pavilion, organized by the ICFO and the Graphene Flagship, Europe's $1 billion research project initiative. The Graphene Pavilion was very impressive, with several companies showcasing real graphene products and prototype devices, and also several research groups from leading Universities. The Pavilion consisted of 11 companies and 9 research centers - and you could see graphene materials, graphene supercapacitors (From Zap&Go, soon to hit the market), large graphene EMI shielding films (from GNext), graphene sensors and graphene-based RFID tags and antennas.

We visited the Pavilion several times, and it was always busy and packed with visitors. The press was very interested and we understood that there were over 70 interviews done during the conference. This was a great opportunity to showcase graphene's potential and expose the new material and technologies to a wider audience - and it seemed that altogether the organizers did a very good job! From our talks during the event, it seemed that both the GSMA (the event organizers) and the graphene flagship were pleased with the event outcome, and the Graphene Pavilion will also be hosted at the MWC Shanghai event later this year, and will also be part of MWC 2017.

Nanomedical Diagnostics launches a new graphene biosensor

Nanomedical Diagnostics, a biotech company that aims to create practical and scalable graphene biological field effect transistor (BioFET) products, announced the completion of its first AGILE (Automatic Graphene Immunolinked Electronic) biosensor Early Access Development Kit test with a lab at the University of Colorado Anschutz Medical Campus.

AGILE requires much less time to deliver data, and a significantly smaller amount of starting material than traditional methods, which is efficient and reduces sample costs. AGILE is the world’s first and only commercially available graphene biosensor. It is an all-electronic, portable, label-free system that provides real-time analysis of biomolecular interactions including kinetics, affinity, and concentration. AGILE sensors are now available to participants in Nanomedical Diagnostics’ Early Access Dev Kit program.

http://www.graphene-info.com/nanomedical-diagnostics-launches-new-graphene-biosensorGraphene achieves superconductivity

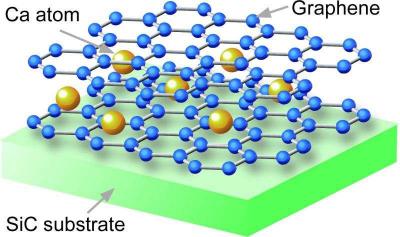

A collaborative team from Tohoku University and the University of Tokyo has designed a way to make graphene superconductive, which means electrons can flow through it with zero resistance. This can lead to significantly more efficient electronic devices, power lines, high-speed electronic devices and more.

While exciting, it is important to note that this demonstration of superconductivity in graphene occurred at a temperature of -269 degrees Celsius, and room temperature superconductivity is still far from attainable. However, this research does suggest that graphene could be used to build nano-sized, high-speed electronic devices.

The researchers in this work have developed a method to grow high-quality graphene on a silicon carbide (SiC) crystal by controlling the number of graphene sheets. The team fabricated bilayer graphene with this method and then inserted calcium atoms between the two graphene layers like a sandwich. They measured the electrical conductivity with the micro four-point probe method and found that the electrical resistivity rapidly drops at around -269 °C, indicative of an emergence of superconductivity.

Haydale news

Haydale's HCS has announced the commissioning of a composite pipe testing facility. The new facility should enable HCS to accelerate the development and approval of new materials and designs that can be used in the construction of oil and gas pipelines. HCS is currently developing new graphene-enhanced polymer materials for use in pipeline construction and this facility will assist greatly in the testing, approval and certification of these novel materials.

Haydale has also received £350,000 in research grants from the government, to accelerate the development of new products enhanced by the incorporation of functionalized graphene and other nanomaterials.

Wrapping graphene oxide around copper nanowires improves its stability in air

Researchers at the University of California at Berkeley and the Lawrence Berkeley National Laboratory have developed a new solution-based, cost-effective way to wrap reduced graphene oxide around the surface of ultrathin transparent conducting copper nanowires. The technique aims to significantly improve the stability of the wires in air and reduce the amount of light scattered by the materials. This could form a new approach to improve and stabilize ultrathin metal nanowires, and could represent a step towards commercializing copper nanowires as low cost transparent conductors for optoelectronic devices.

Thin films made of the wires might be used in optoelectronics devices, particularly in displays and flexible electronics. Metal nanowire films could make good replacements for the expensive and brittle indium tin oxide (ITO) in next-generation electronics, thanks to their excellent electrical and optical properties and the fact that they can be easily processed in solution. Wrapping graphene around these nanowires not only improves their stability in air but also the electrical and thermal conductivity of the metal wires.

The problem of costs remains, however, as plasma CVD at temperatures as high as 500–700°C is required to grow the thin layer of graphene on the nanowires – a method that is still too expensive for producing large quantities of the material. The scientists have addressed this problem with a room-temperature solution-based technique to produce high-quality ultrathin copper reduced-graphene-oxide-core-shell nanowires. The films made from these coated copper nanowires are highly transparent and at the same time have low electrical resistivity. They are very stable in air and perform well at high temperatures and in humid environments. They can even be mechanically deformed and are thus ideal for making flexible electrodes. They do not scatter light, so could be used in display applications.

Elcora Advanced Materials announced starting construction of graphene facility

Elcora Advanced Materials announced that it has started construction of its graphene production facility. Elcora is constructing its own graphene production facility in the Canadian city of Halifax, Nova Scotia to supply high quality graphene.

The plant is meant to have a modular design in which each "line" will be able to produce 100 kg of graphene per year. The plant will use a graphite precursor specially processed and refined for the Elcora graphene process within the vertically integrated supply chain. Installation is anticipated to commence in February and March of 2016 with full production anticipated within the second quarter of 2016.

Graphene-Info's Graphene Investment Guide

Make sure to get your copy of our new report, a comprehensive and helpful guide to investing in graphene. The graphene market and industry are still in early stages - but savvy investors are hurrying to find the companies that will profit the most from the oncoming revolution. Our investment guide will help establish a graphene investment paradigm and assist in launching a successful graphene portfolio.

Our new Graphene For The Mobile Industry article

Don’t miss our latest article: graphene’s diverse and impressive potential for the mobile industry. This article is a Graphene-Info independant piece, especially designed to provide an introduction to the many applications of the mobile market that can be transformed by graphene..

AEM2016: International conference on Advanced Energy Materials

AEM2016 (September 12-14, 2016), the first international conference on Advanced Energy Materials, will be conducted at the University of Surrey, Guildford, England along with the 8th international conference on Advanced Nanomaterials and the 2nd international conference on Hydrogen Energy.

The three-day conference will host parallel symposiums, poster presentations and networking opportunities. The AEM conference will also host a dedicated Graphene Technology session.

The Centre for Process Innovation (CPI) has opened the doors of a Graphene Centre that aims to help companies develop, prove and commercialize products using graphene technologies. The Graphene Centre was funded by Innovate UK to support the commercial growth of the UK graphene industry and operates two specialized facilities at NETPark in Sedgefield, County Durham.

Sunvault Energy and Edison Power Company announced that they have signed a solar energy generation and large scale battery storage project in Delaware. The total size of the project is 484kW with both Solar Photovoltaics and 600kW/300kWh Battery Storage for 3 fire stations. The Company plans to utilize the Sunvault / Edison Graphene Electrical Energy Storage device (EESD) as the "battery" component within the projects, further demonstrating the technology in actual field.

American Graphite Technologies announced that it has extended its agreement with the Kharkov Institute of Physics and Technology (KIPT) and Science and Technology Centre in Ukraine (STCU) to further its research of its 3D graphene printing project, called P-600. The project was launched in 2013, as a cooperation between these institutes to research the possibility of using graphene-based materials as the working materials for 3D printing.

Thomas Swan, manufacturer of performance and specialty chemicals, has announced that it has received funding from Innovate UK, the UK’s innovation agency, for two new collaborative projects in a program entitled “Advancing the Commercial Applications of Graphene”. Both projects are due to start on 1st April 2016.

The Spanish Graphenano claims to have recently introduced, together with its Chinese partner Chint, graphene polymer batteries that reportedly allow for a range of 800 kilometers in electric vehicles and can be charged in a few minutes. The batteries are meant for domestic use, in the automotive sector (both cars and bicycles), drones or even pacemakers.

An international collaboration of scientists from the University of Basel and the Swiss Empa have studied the above-average lubricity of graphene using a two-pronged approach combining experimentation and computation in order to better understand the manipulation of chemicals at the nano level and pave the way for creating frictionless coatings. The experiments revealed almost perfect, frictionless movement.

Researchers at Aalto University in Finland have fabricated an electricity-conducting material with promising properties by merging graphene and another 2D material, gallium selenide. The newly designed heterojunction could prove important for applications like sensors and wearable electronics and are, in comparison similar components that contain silicon, extremely thin. They also have impressive properties and the method used for their preparation is simpler than previous researched methods.

Researchers at Kansas State University, University of Buffalo and the State University of New York have designed a new technique for 3D printing graphene aerogels with complex microstructures. The technique combines drop-on-demand 3D printing with freeze casting.

A collaborative team of scientists from the U.S. Department of Energy's (DOE) Brookhaven National Laboratory, Stony Brook University (SBU), and the Colleges of Nanoscale Science and Engineering at SUNY Polytechnic Institute have developed a simple method for creating resilient, customized, and high-performing graphene: layering it on top of common glass. The scalable and inexpensive process may help pave the way for a new class of microelectronic and optoelectronic devices-from efficient solar cells to touch screens.

UK-based scientists from BAE Systems and the University of Surrey have discovered that patterned graphene sheets, inspired by moths’ eyes, could be used to capture light to produce energy or power sensors, and could also be used to develop “smart wallpaper” capable of powering Internet of Things applications.

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!