The Graphene-Info newsletter, July 2015

Published: Wed, 07/01/15

Samsung to double Li-ion battery life using graphene |

Samsung researchers reportedly developed materials that can be used to double the capacity of Li-ion batteries. The key to the more efficient batteries is a new graphene-based cathode material. It is a new silicon cathode material "with high-crystalline graphene". As deployed in its lithium-ion batteries the new cathodes produce cells "with twice as much capacity as ordinary lithium-ion batteries," according to various reports.

This research presents a dramatic improvement of the capacity of lithium-ion batteries by applying a new synthesis method of high-crystalline graphene to a high-capacity silicon cathode. Samsung's team used silicon cathodes instead of graphite ones; this is not a novel approach, since many previous studies have also used it. The challenge, however, is that the silicon can expand or contract during the battery charging and discharging cycles. Samsung addressed this issue by creating a process to grow graphene cells directly on the silicon in layers that can adjust to allow for the silicon's expansion: "The graphene layers anchored onto the silicon surface accommodate the volume expansion of silicon via a sliding process between adjacent graphene layers. When paired with a commercial lithium cobalt oxide cathode, the silicon carbide-free graphene coating allows the full cell to reach volumetric energy densities of 972 and 700 Wh l-1 at first and 200th cycle, respectively, 1.8 and 1.5 times higher than those of current commercial lithium-ion batteries."

Samsung apparently intends to improve the technology and hopefully deploy it in both the mobile device and electric vehicle markets, but it will probably take quite a few years since this project, while promising, is still in research phase.

Graphene enables tiny bulb on a chip |

A team of scientists from Columbia, Seoul National University (SNU), and Korea Research Institute of Standards and Science (KRISS) reported the creation of an on-chip visible light source using graphene as a filament. Creating light in small structures on the surface of a chip is crucial for developing fully integrated 'photonic' circuits that do with light what is now done with electric currents in semiconductor integrated circuits.

The scientists attached small strips of graphene to metal electrodes, suspended the strips above the substrate, and passed a current through the filaments to cause them to heat up. The team refers to this design as 'the world's thinnest light bulb', a type of 'broadband' light emitter that can be integrated into chips and may pave the way towards the realization of atomically thin, flexible, and transparent displays, and graphene-based on-chip optical communications.

Previous attempts to put an incandescent light bulb onto a chip failed since light bulb filaments must be extremely hot in order to glow in the visible range and micro-scale metal wires cannot withstand such temperatures. In addition, heat transfer from the hot filament to its surroundings is extremely efficient at the microscale, making such structures impractical and leading to damage of the surrounding chip. In this study, however, the team managed to show that the graphene reached temperatures of above 2500 degrees Celsius, hot enough to glow brightly.

The team also demonstrated the scalability of their technique by designing large-scale arrays of CVD graphene light emitters. The scientists are currently working to further characterize the performance of these devices and to develop techniques for integrating them into flexible substrates.

Skeleton Technologies to launch new graphene-based supercapacitors |

Skeleton Technologies announced the launch of a new range of supercapacitors that are said to offer the highest level of energy density on the market. Through the use of patented graphene material, the new series boasts a capacitance of 4500 farads. The company claims that the closest competitor product has a capacitance of only 3400 farads.

Skeleton Technologies plans to use the SkelCap 4500 series to maximize opportunities in the heavy transportation and industrial markets where weight and space are at a premium. The new range has been designed for mass-market applications and the needs of systems engineers. In addition, the company aims to announce the first supercapacitor product for the hybrid truck market during next month.

Bosch creates magnetic sensor 100 times more sensitive than silicon equivalent |

A collaboration between Bosch, the Germany-based engineering giant, and scientists at the Max-Planck Institute for Solid State Research yielded fascinating results, shown in a presentation during Graphene Week 2015. The researchers jointly created a graphene-based magnetic sensor 100 times more sensitive than an equivalent device based on silicon.

The research team used hexagonal boron nitride as substrate for the magnetic sensor, which is based on the Hall effect (a magnetic field that induces a Lorentz force on moving electric charge carriers, leading to deflection and a measurable Hall voltage). Graphene's high carrier mobility makes it useful in sensing applications, and the results achieved by the Bosch-led team confirm this. The presentation displaying the team's results showed that the worst case graphene scenarios roughly match a silicon equivalent. In the best case scenario, the result is a huge improvement over silicon, with much lower source current and power requirements for a given Hall sensitivity. In short, graphene provides for a high-performance magnetic sensor with low power and footprint requirements.

The remarkable result focused on a direct comparison between the sensitivity of a silicon-based Hall sensor with that of the Bosch-MPI graphene device. The silicon sensor has a sensitivity of 70 volts per amp-tesla, whereas with the boron nitride and graphene device the figure is 7,000. That is a significant two orders of magnitude improvement. Following this remarkable result, Bosch stated that it regards graphene as a strong material suitable for commercial application.

Graphene 3D Lab updates |

Graphene 3D Lab has accepted delivery of additional extrusion equipment that will double the potential production capacity of their functional filaments. This equipment will also be used to manufacture the company's specialty filaments including the recently introduced conductive filament sold through the company's on-line store.

The company also announced a distribution and manufacturing partnership with Polymaker. Under the terms of the agreement, Polymaker will distribute all Graphene 3D manufactured specialty and functional filaments and provide filament manufacturing services on an as required basis. Polymaker's manufacturing operation is located in China, and the company operates sales and distribution offices in China, New York, USA, Netherlands and Japan.

Graphene 3D's on-line filament store will carry unique Polymaker filaments, including PolyMax PLA, PolyFlex, and PolyWood. Both companies plan to start offering each other's products on their respective on-line stores in July. The agreement also includes provisions for Graphene 3D and Polymaker to collaborate on the development of an expanded line of graphene filaments.

An additional agreement was signed with Ideum, a company situated in New-Mexico which develops large-scale smart-tables and walls. The agreement lays the foundation for joint research, product development, and marketing between the two companies.

Graphene 3D and Ideum will evaluate and co-develop products by Graphene 3D which can be used as capacitive sensors to interface with Ideum's products. Graphene 3D will also begin commercial on-demand 3D printing of coasters, joysticks, and styluses which Ideum clients can use to interact with their smart-tables. For example, styluses of various shapes, 3D printed in Conductive Graphene Filament, may be used as brushes used in photo editing software to give a more hands-on feel to creative work done on an Ideum smart-table.

Japanese paper-cutting techniques to enable graphene-based flexible gadgets |

A research team at the University of Michigan utilized Japanese paper cutting techniques, called kirigami, to create a new type of flexible conductor. The team believes that this technique may open up significant possibilities for implantable medical devices, which have to flex and bend within the human body to work. Another option is gadgets that won't break when bending or flexing.

The first prototype of the kirigami stretchable conductor consisted of tracing paper covered in carbon nanotubes. The layout was quite simple, with cuts like rows of dashes. Later concepts were more intricate. for example, conductor sheets made out of graphene oxide, with etching cuts into the surface just a tenth of a millimeter long using laser beams and a plasma of oxygen ions and electrons.

Our new Graphene paints article |

Don’t miss our latest article on graphene paints, an interesting field in which graphene can go a long way towards improving existing products and creating many new ones.This article is a Graphene-Info independent piece, especially designed to provide an introduction and an informative market status.

Graphene-Info's Graphene Batteries Market Report |

We're happy to announce our first graphene market report, the Graphene Batteries Market Report. This report is a comprehensive guide to graphene-enhanced batteries with valuable market insights, and covers everything you need to know about graphene in this field. This is a great report for anyone involved with the battery market, nanomaterials, electric vehicles and mobile devices.

Reading this report, you'll learn all about:

- The advantages using graphene batteries

- The different ways graphene can be used in batteries

- Various types of graphene materials

- What's on the market today

The report package also provides:

- A list of all graphene companies involved with batteries

- Detailed specifications of some graphene-enhanced anode materials

- Personal contact details into most graphene developers

- Free updates for a year

We are now offering this market report for a special launch price of $199.99 (for a single user license, site and enterprise licenses are available too). You can find out more information and download the report here.

Top Graphene News |

Haydale signs reactor supply agreement with CPI

Haydale announced inking a deal to supply the Centre for Process and Innovation (CPI) in the UK with its HT60 reactor, which is expected to be fully operational by October 2015 and produce an initial revenue of ₤170,000 for Haydale.

A new process that forms 3D shapes from flat sheets of graphene

Researchers from the University of Illinois at Urbana-Champaign have developed a new approach for forming 3D shapes from flat sheets of graphene that may open the door to future integrated systems of graphene-MEMS hybrid devices and flexible electronics.

IBM issues patent for a graphene-based identification system

Recent reports indicate the issue of a patent assigned to IBM, regarding a graphene resistor based tamper resistant identifier with contactless reading. The invention seems to relate to an identification system that is more immune to copying than traditional barcodes.

ETRI scientists develop graphene-based textile sensor for gas detection

A team of scientists from ETRI in Korea announced the development of a washable, flexible and highly-sensitive textile-type gas sensor that will make it possible for firefighters to check the condition of the air through a connected device by wearing work clothes with gas sensors made from such textiles.

2-DTech achieves major advance in graphene production

Versarien, the advanced engineering materials group, recently announced that its graphene development subsidiary, 2-DTech, has achieved a major breakthrough in graphene production. The 2-DTech production process provides significant amounts of single layer graphene on an industrial scale.

Graphene Nanochem wins $28 million order for new drilling fluid

Graphene Nanochem announced a significant order for its PlatDrill Series drilling fluid worth $28 million with an undisclosed national oil company.

Graphenea secures $2.5 million to build a new graphene pilot plant

Graphenea, the leading graphene manufacturer and supplier, announced plans to construct a new graphene pilot plant. $2.5 million will be invested in building the plant, which is meant to be opened in 24 months and multiply production capacity by 200 times.

Cerious Technologies has graphene-based interconnects on the market

An American company called Cerious Technologies is now offering several types of graphene-based cables and interconnects for sale. Cerious is focused on manufacturing and selling audio products like speakers, sound systems and various audio cables and interconnects.

Xefro plans to launch graphene-based heating system in July 2015

The UK-based Xefro has created a graphene-based heating system called gRAD that can reduce energy costs up to 70% and quickly switch on and off. The heating system is planned for launch in July 2015 in the UK.

Carbon Sciences to develop graphene-based devices for cloud computing

Carbon Sciences announced its plans to develop graphene-based devices for cloud computing. Graphene-based fiber optics components, such as photodetectors, fiber lasers and optical switches, are expected to unclog the existing bottlenecks and enable ultrafast communication in data centers for Cloud computing.

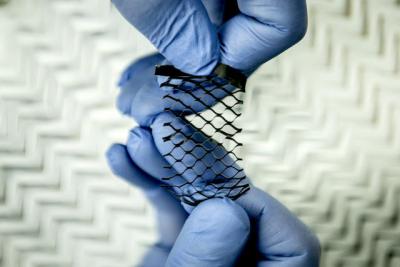

Strategic Energy Resources enters contract to commercialize graphene membranes

Strategic Energy Resources has entered into an exclusive worldwide licence to commercialize graphene membrane for separation. SER's wholly-owned subsidiary Ionic Industries will have full rights to exploit and commercialize the product.

Send this to a friend |

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the

world of Graphene.

If you received this email from a friend, subscribe to this

newsletter here!