The Graphene-Info newsletter (August 2015)

Published: Mon, 08/03/15

Graphene-based film to cool down electronic devices |

Researchers at Chalmers University of Technology in Sweden demonstrated how graphene films can be used for the efficient cooling of electronic devices. Disposing of excess heat in efficient ways is imperative to prolonging electronic lifespan, and would also lead to a considerable reduction in energy usage.

In 2013, Chalmers researchers had observed the impact of graphene in having a cooling effect on silicon-based technology. This earlier technique, however, was filled with problems since it consisted of only of a few layers of thermal conductive atoms and could not be used to rid electronic devices of great amounts of heat. Researchers tried to resolve this issue by stacking additional layers of graphene to augment its effect, but it ended up revealing yet another issue - as extra layers are added, it significantly lessens the ability of graphene to remain adhered to the electronic device.

The scientists were able to resolve this problem by adding (3-Aminopropyl) triethioxysilane (APTES) molecules to functionalize the graphene and create stronger bonds. The graphene film effectively functions as a coolant, preventing devices to heat up to the point where they start to malfunction. The technique helps the system reach a capacity of four times the capacity that could be scaled via copper.

A novel method yields large graphene crystals in a matter of minutes |

Oxford University scientists demonstrated how millimeter-sized crystals of high-quality graphene can be made in minutes instead of hours. In about 15 minutes, the method can produce large graphene crystals (around 2-3 millimeters in size) that it would otherwise take up to 19 hours to produce using current chemical CVD techniques.

The researchers took a thin film of silica deposited on a platinum foil which, when heated, reacts to create a layer of platinum silicide. This layer melts at a lower temperature than either platinum or silica, creating a thin liquid layer that smooths out nanoscale 'valleys' in the platinum so that carbon atoms in methane gas brushing the surface are more inclined to form large flakes of graphene.The scientists state that the rapidly created graphene is of a comparable quality to anything other methods are able to produce. Since it is allowed to grow naturally in single graphene crystals, there are no grain boundaries are promoted that can negatively affect the mechanical and electrical properties of the material.

This method may open up many possibilities for cost-reduction and larger-scale graphene production for applications where very high quality graphene is needed. Beyond speed and quality, the method could also have additional benefits: with a thicker liquid layer to insulate it the graphene might not have to be removed from the substrate before it can be used - a costly and time-consuming additional step required with all other methods.

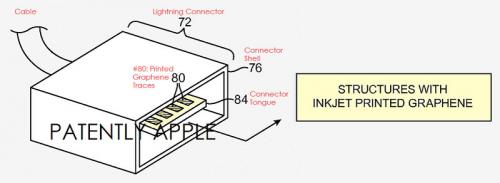

Apple patents Lightning connectors with graphene signal paths |

Apple recently submitted a patent application for lightning connectors that use graphene signal paths. In Apple's patent a connector (lightning connector) is coupled to a signal cable. The inkjet-printed graphene traces are formed on the upper and/or lower surfaces of the plastic connector tongue.

A connector can be provided with dielectric material and conductive traces, some of which can be made using printed circuits. Graphene traces may be deposited using inkjet printing techniques or other deposition and patterning techniques. During inkjet printing, graphene may be patterned to form signal lines on a connector structure, printed circuit, contacts on a printed circuit board and other structures. Graphene paths such as graphene trace may be formed on the surface of the structure. For example, the inkjet printing equipment or other suitable graphene deposition equipment may be used in depositing graphene onto the surface of the structure. Inkjet printing equipment may include one or more printing heads such as printing heads that supply graphene in liquid form. Once deposited onto the structure, the liquid material in which the graphene is deposited may be evaporated (at room temperature or at an elevated temperature), leaving graphene traces such as graphene trace on the structure.

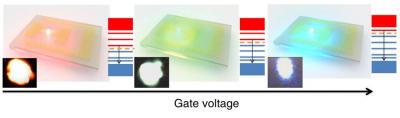

Graphene to enable color-tunable LEDs |

Researchers from Tsinghua University in Beijing demonstrated a graphene-based LED that not only can be tuned to emit different colors of light, but can do so across nearly the entire visible spectrum: from blue (450-nm wavelength) to red (750-nm wavelength)—basically all colors but the darkest blues and violets. Such a color tunable LED has never before been realized.

The scientists made the light-emitting material from the interface of two different forms of graphene. These forms are graphene oxide (GO) and reduced graphene oxide (rGO). Placed at the interface of the GO and rGO is a special type of partially reduced GO that has optical, physical, and chemical properties that lie somewhere in between those of GO and rGO. The most important "blended" property of the interfacial layer is that it has a series of discrete energy levels, which ultimately allows for the emission of light at many different energies, or colors.

In their work, the researchers fabricated and tested 20 graphene-based LEDs. Overall, the devices demonstrated good brightness but low efficiency, which they plan to improve. Another drawback of the current prototype is a very short emission lifetime of less than a minute or so in ambient conditions and about 2 hours in vacuum. The researchers attribute the short lifetime to oxidation in the air and predict that protective coatings may improve this area.

Experts differ on graphene’s future |

Lux Research recently came out with a rather menacing prediction that graphene is destined to become the "next carbon nanotube". This statement refers to the massive hype that surrounded carbon nanotubes in the past, which failed to be followed by actual commercial success. Lux Research believes that graphene, despite its impressive properties and seemingly endless possibilities, will not follow in silicon's footsteps and find ubiquitous applications, but rather become closer to carbon nanotubes and find limited uses in somewhat niche markets.

Lux names three major reasons for their prediction. The first is over-aggressive capacity expansions coupled with limited commercial demand. A second reason touches on the issue of undistinguished and unproven suppliers, which constitute much of the graphene market. The final reason given by Lux is the lack of concrete performance metrics demonstrating true value proposition in most segments.

IDTechEx, on the other hand, much more optimistically predicts that the graphene market will reach nearly $200 million by 2026, with the estimation that the largest sectors will be composites, energy applications and graphene coatings.

Graphene inks are said to be constantly improving (while their prices seem to be dropping), which might promote, among others, applications like sensor electrodes and smart packaging. In the transparent conductive film industry, however, it is estimated that graphene will not be able to compete with ITO films.

In the supercapacitors field, the report states that major obstacles that graphene electrodes face, which need to be overcome in order to see greater market acceptance, are graphene stacking, poor surface utilisation and poor out-of-plane conductivity, suggesting that it might be difficult for graphene to replace activated carbon in this area.

The researchers noted that graphene additives for battery electrodes have already been launched. The additives reduce resistance in lithium ion batteries and are also able to reduce mechanical breakage in silicon anode batteries. Graphene additives are also used to enhance the performance of composites, according to the report. The results are said to be promising for thermal composites.

Furthermore, the report says that a range of early stage applications are emerging that could result in graphene being used in sensors, water filtration membranes and anti-corrosion applications in the future.

Berkeley scientists design graphene-based loudspeakers and microphones |

Researchers at the University of California, Berkeley, used graphene to build lightweight wireless ultrasonic loudspeakers and microphones. These devices complement standard radio transmission using electromagnetic waves in areas where radio is impractical, such as underwater, but with far greater fidelity than current ultrasound or sonar devices. They can also be used to communicate through objects, such as steel, that electromagnetic waves can’t penetrate.

Speakers and microphones both use diaphragms, typically made of paper or plastic, that vibrate to produce or detect sound. The diaphragms in the new devices are graphene sheets that have the right combination of stiffness, strength and lightness of weight to respond to frequencies ranging from subsonic (below 20 hertz) to ultrasonic (above 20 kilohertz). Graphene is thin enough to respond immediately to pulses, and is very light so it is able to generate sharp pulses and measure distance much more accurately than traditional methods. The human hearing range is from 20 hertz up to 20,000 hertz, whereas bats hear only in the kilohertz range, from 9 to 200 kilohertz. The graphene loudspeakers and microphones operate from well below 20 hertz to over 500 kilohertz.

The scientists say that these devices could be one of the applications closest to commercial viability, since they have worked out how to make the graphene and mount it, and it’s relatively easy to scale up. The researchers state that the graphene loudspeakers will please audiophiles as they provide excellent sound quality and flat response. They even predict that these new microphones could be incredibly valuable for studying auditory signals at high frequencies, such as the ones used by bats. The use of graphene allows the scientists to obtain very flat frequency responses in a wide range of frequencies, including ultrasound, and will permit a detailed study of the auditory pulses that are used by bats.

Top Graphene News |

A tunable graphene-based sensor for the detection of nanomolecules

Researchers at EPFL's Bionanophotonic Systems Laboratory (BIOS) together with researchers from the Institute of Photonic Sciences (ICFO, Spain) have harnessed graphene's unique optical and electronic properties to develop a reconfigurable and highly sensitive sensor that detects molecules like proteins and drugs.

Advanced Graphene Products to develop graphene-based yacht components

The Polish graphene producer Advanced Graphene products (AGP) and Lodz University of Technology have launched a joint project to produce flexible graphene components for yachts. They plan to develop a technology that will rely on fibre-graphene components that will allow to reduce the weight of various elements while preserving, and even increasing their strength and elasticity.

Haydale activity updates

Haydale has announced two collaboration agreements, with Australian technology materials development company Talga Resources to jointly explore industrial scale business cooperation opportunities, and with Versarien (main owners of 2-DTech) to accelerate the development of their respective graphene

projects. Haydale also announced further progress in North America in the form of a service agreement with InVentures Groups, as well as the opening of a new office.

Angstron Materials secures $5 million to expand business and commercialize key products

The U.S-based graphene materials producer and applications developer Angstron Materials announced securing $5 million in capital to increase manufacturing capacity for its single and few-layer graphene materials and bring key technologies to market.

Monash and Ionic cooperate to design graphene-based supercapacitors

Ionic Industries, a spin-off of minerals explorer Strategic Energy Resources, cooperated with Monash University to develop extremely thin graphene-based supercapacitors, able to store large amounts of energy. According to Ionic, the first battery prototype should be available within six months and more sophisticated prototypes in three to five years.

Israeli and Australian scientists come up with a fast and efficient method of producing graphene

Researchers at the Israeli Ben-Gurion University of the Negev (BGU) and University of Western Australia have designed a new process for creating few-layer graphene for use in energy storage and other material applications that is faster, potentially scalable and surmounts some of the current graphene production limitations.

The University at Buffalo receives an $800,000 grant from the Navy to work on graphene-based next-gen power technology.

The University at Buffalo has received an $800,000 grant from the Navy to work on graphene-based next-generation power technology. The Office of Naval Research grant will fund UB engineers' work on the development of nanoribbons of graphene. Buffalo University says the project comes as the Navy seeks alternatives to conventional power control systems.

Rice scientists calculate how twisting graphene changes its electrical properties

Researchers at Rice University used computer models to demonstrate that twisting graphene alters its electrical properties, and produce what is known as a flexoelectric effect in which a material exhibits a spontaneous electrical polarization brought on by a strain.

Alabama Graphite raises $2.875 million in a private placement

Alabama Graphite announced the closing of a $2.875 million private placement. The company issues 14,375,000 units at $0.2 each, and each unit comprises of a common share and one-half of a common share purchase warrant ($0.35 exercise price).

Send this to a friend |

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the

world of Graphene.

If you received this email from a friend, subscribe to this

newsletter here!