The Graphene-Info Newsletter (February 2015)

Published: Tue, 02/03/15

Mass production of graphene for 3D print |

Graphene 3D Lab announced that it has received and assembled an industrial scale thermoplastic extruder line, to be used in the production of conductive graphene filament. The equipment has a production capacity of up to 10 kg per hour of 3D printer filament and is now operational. The company states that sales of conductive graphene filament are expected to begin around March 2015.

Magnetic graphene |

Researchers at the University of California at Riverside found a way to introduce magnetism in graphene while still preserving electronics properties. This may represent a significant step forward in the use of graphene in chips and electronics, since doping in the past induced magnetism but damaged graphene's electronic properties.This method can also be used in spintronics - chips that use electronic spin to store data. The UC-Riverside researchers claim this technique also enhanced spin-orbit coupling that is believed to be inherently weak in graphene. The proximity-induced magnetism in graphene could lead to novel transport phenomena that are potentially useful for spintronics.

Will Tesla’s Roadster have a graphene-enhanced battery? |

A few days ago, Tesla announced the implementation of several improvements to their Roadster model, one of which involves an intriguing battery enhancement. Tesla claims to have identified a new cell technology that has 31% more energy than the original Roadster cell. Using this new cell, the company created a battery pack that delivers roughly 70kWh in the same package as the original battery.

Although graphene was not specifically mentioned in this statement, it does stand to reason as a Chinese website stated that the Roadster 3.0 "uses graphene in the production of the battery, which increases its energy storage capacity significantly. The battery range improves by 50% which enables the 3.0 version to travel 644 km on one charge".

Graphenea sales more than double in 2014 |

Graphenea announced the closing of a successful financial year, with 2014 sales at over $1.2 million. This figure means that the company more than doubled its 2013 results. In addition, the company relays it has a positive cash flow, making it a profitable business. Graphenea maintains that most of its customer base has returned for orders last year, making a statement about the reliably and high quality of the graphene on sale.

Controlling GNPs' edge properties |

Researchers at Rice University managed to prove it possible to determine the edge properties of graphene nanoribbons by controlling the conditions under which the GNRs are pulled apart. These properties bear great importance for various applications, electronics being among the leading ones. This ability is meant to assist in making graphene with the right type of edge to match the required properties for an application, and could be very helpful in making graphene-based nano devices by way of mechanical fracture.

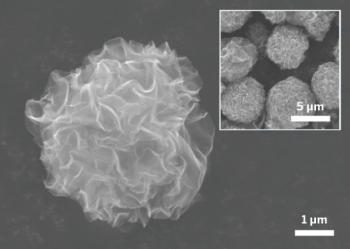

Pompom-shaped graphene |

Korean Scientist at the university of Yonsei in Seoul and the Korean Institute of Ceramic Engineering & Technology designed round graphene microparticles by spraying graphene oxide droplets into a hot solvent. This technique could pose a versatile and simple approach to making electrode materials for batteries and supercapacitors with improved energy and power densities.

The capacitance of the pompom-like graphene electrodes is similar to that of other electrodes made with 3D graphene materials, but the novel technique makes this work unique and important because it is direct, simple, and quite easy to scale up for industrial applications, according to the scientists. Another key advantage is that the method allows functional nanoparticles to be trapped directly into the microspheres to form nanocomposites.

The Graphene-info team at the 2015 LOPEC |

LOPEC (large-area, organic & printed electronics convention) is a leading international exhibition and conference for the printed electronics industry. LOPEC will host international market leaders aiming to present innovations, latest materials and groundbreaking processes to all walks of industry folk.

The Graphene-Info team will attend this conference! If you wish to contact us and schedule a meeting, simply reply to this mail.

Top Graphene News |

Xolve raises $1.8 million to deploy their nanomaterials process

Xolve, an american nanotechnology firm, raised $1.8 million (of a proposed $2.8 million funding round), with twenty-one investors taking part in the funding so far. This brings the amount the company raised in the last four years to $6.4 million. The company seeks to deploy a nanomaterials process developed at the University of Wisconsin-Platteville for a variety of applications.

President Obama's graphene adventure

President Obama recently visited Boise State University to take in some of the school's 3D printing technology, as well as the new College of Innovation. Obama went to Boise State’s College of Engineering and the school’s New Product Development Lab, to witness their work on 3D printing electronics, using flexible, light, and conductive graphene nano-materials, which can be printed in stacks onto small, inexpensive sensors, and resistors.

Will graphene adaptation 'GraphExeter' replace ITO?

University of Exeter scientists discovered that GraphExeter, an adaptation of graphene, is durable to prolonged exposure to high temperatures and humidity. This makes the material not only a transparent, flexible and lightweight conductor, but a resilient one at that. The scientists predict major importance of this discovery for various electronic applications (and a possible ITO replacement).

UK's CPI plans to turn food waste into graphene and renewable hydrogen

UK-based Centre for Process Innovation (CPI) is leading a European three-year collaboration called PlasCarb that aims to transform food waste into a sustainable source of graphene and renewable hydrogen. The project, will focus on transforming biogas generated by the anaerobic digestion of food waste using an innovative low energy microwave plasma process to split biogas (methane and carbon dioxide) into said products.

KAIST develops a novel graphene transfer method

Researchers at the Korean KAIST developed a technique for the delamination of single-layer graphene from a metal etching, that enables different types of transfer methods such as transfer onto a surface of a device or a curved surface, and large surface transfer onto 4 inch wafers. This method could be helpful for wearable smart gadgets and various graphene electronic devices.

Researchers use graphene to fight resistant cancer cells

Researchers from the Amrita Centre for Nanoscience and molecular Medicine in India developed a simple graphene-based method of thermally ablating highly resistant cancer cells. The method involves biodegradable graphene nanoparticles, which were found to be able to convert non-ionizing radio waves into heat energy at microscopic levels.

Graphene Nanochem announces profitable Q4 in 2014

UK's Graphene Nanochem announced a profitable fourth quarter in 2014 partly thanks to successful sales of its PlatDrill and PlatQuartZ products. This profit is especially noteworthy in light of former projections by the company that warned of losses due to delays in the deployment of its PlatDrill series.

Penn students propose a way to use graphene to measure frac water contamination

Students at the University of Pennsylvania’s Wharton school have designed a graphene-based way to measure ground water contamination from leaking fracking fluids. Using graphene, the students can measure benzene even in picomolar amounts (as graphene is several millions times thinner than a piece of paper, which allows it to have a high surface to volume ratio).

UK researchers working towards graphene standardization

The NPL (National Physical Laboratory) and the University of Manchester are cooperating on a project to design characterization techniques that can be used in real time on large amounts of graphene. One such technique is microwave measurement, where a graphene film is placed in a microwave field and disturbs the field. The extent of the disturbance indicates the sheet resistance and conductivity.

A $500,000 award to study crumpled graphene oxide Nanocomposites for advanced water treatment

A scientist from the American Washington University received the prestigious Faculty Early Career Development Award (CAREER) from the National Science Foundation (NSF). The five-year, $500,000 award will fund his efforts to develop 3D nanoscale composites made of crumpled graphene oxide as multifunctional platform materials for advanced water treatment technologies.

Unique encapsulation may advance graphene devices

Researchers from AMO GmbH and Graphenea demonstrated a unique encapsulation technique that enables highly reproducible operation of graphene devices in normal atmosphere for several months. This encapsulation may help in solving one of the major problems of graphene-based devices - sensitivity to environmental elements like humidity or gases.

Send this to a friend |

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the world of Graphene.

If you received this email from a friend, subscribe to this newsletter here!