The Graphene-Info newsletter (April 2015)

Published: Wed, 04/01/15

Graphene 3D Lab sells conductive graphene filament for 3D printing |

Graphene 3D Lab announced that it has launched commercial sales of its conductive graphene filament for 3D printing. The filament incorporates highly conductive proprietary nanocarbon materials to enhance the properties of PLA, a widely used thermoplastic material for 3D printing.The filament is therefore compatible with most commercially available 3D printers. The conductive filament can be used to print conductive traces (similar to as used in circuit boards) within 3D printed parts for electronics.

The company's conductive filament is to be distributed through the Company's recently launched brand and e-commerce platform, Black Magic 3D, established as the trade name for all current and future Graphene 3D filaments.

The NGI is officially open and implies graphene LEDs for sale |

The National Graphene Institute at The University of Manchester has been officially opened, in an opening ceremony that included dignitaries, scientists and business leaders.

The NGI’s official opening also included Professor Sir Kostya Novoselov’s demonstration to the Chancellor of the Exchequer George Osborne of the graphene light bulb, which is mentioned to be set to launch later in 2015. While the price is yet unknown, it is rumored to be relatively low-price, cut energy use by 10% and last longer owing to its conductivity.

The first graphene phone on the market! |

The first mass produced graphene-enhanced phone is reportedly up for commercial sale by Chinese companies. Now, further details are available as it seems that the device is available on the company's website.

The phone, called the Galapad Settler, is said to use graphene for its touchscreen, as well as casing and battery. 30,000 pieces were made by Chinese graphene company Moxi together with Chinese device maker Galapad, with each device selling for $399 USD. Graphene is allegedly used in the phone's 5.5-inch phone’s touchscreen, 3000-mAh battery and case. The phone runs off a 64-bit quadcore Snapdragon 410 processor along with 2GB RAM and has 16GB of internal storage. The device has a 8 megapixel camera and a 5MP camera on the front. The companies claim that the touchscreens made with graphene are able to transmit more light and so can produce better colours and are more sensitive than conventional ones. The use of graphene in batteries raises the charge density by 10% and extends the overall battery life by 50%.

3D printed customized graphene-enhanced cars |

U.S-based Local Motors plans to 3D print vehicles within 12 hours, reinforcing extruded printed material with graphene. The company reports significant progress in its additive manufacturing technology since it unveiled its Strati vehicle (pictured) last September.Local Motors announced plans in January this year to open two “microfactories” in the US, and plans 50 such factories worldwide over the next five years.

The plan is to eventually offer opportunities for people to submit their own designs, to offer a high degree of customisability and to provide credit incentives to return cars to have material recycled. The company is looking to reduce the print time to 12 hours, with a four to five-hour assembly time, and had been speaking to a Korean firm about sourcing graphene for extruding in composite 3D printing materials.

Sunvault to develop graphene-based supercapacitors for PV cells |

Canadian Sunvault Energy has formed the Supervault Energy JV to develop UCLA-patented graphene supercapacitor technology. It announced its plans to soon enter a joint venture which "change the face of renewable energy generation and storage".

The company states that graphene will enable devices that recharge in seconds and that supercapacitors could be scaled up from portable devices, such as smartphones, to charging stations for electric vehicles. The company says that the technology can be scaled up to utility-sized applications and that it intends to incorporate the technology in its solar cells to produce a device capable of generating, transferring and storing energy in one unit.

Advances position NanoXplore as leading graphene company |

Recent news from NanoXplore, including successful $2.7M financing round and launch of their three tonnes/year production facility, have positioned the company as a leading graphene company, and a major player in North America. NanoXplore is positioning themselves not only as a large volume producer of graphene, but also as a solutions developer for applications such as smart textiles, Li-ion batteries, lubricants, paints, and polymers.

The core of the company appears to be their production process, developed in-house. In addition to large capacity, they claim it creates very high quality (low defect) graphene, functionalized during production to facilitate mixing (dispersion) with a broad range of industrial materials. The range of products shows not only high quality graphene powders, but also a couple of unique offerings. Interestingly, they seem open to licensing their production technology.

This post has been sponsored by NanoXplore.

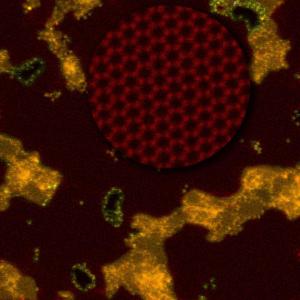

Nanoporous graphene membrane for desalination |

A team of scientists led by the Department of Energy's Oak Ridge National Laboratory (ORNL) demonstrated an energy-efficient desalination technology that makes use of a porous membrane made of free-standing, porous graphene.

The scientists report that the flux through these graphene membranes was at least an order of magnitude higher than the water that pass through state-of-the-art reverse osmosis polymeric membranes. Many of the current methods for purifying water require a significant amount of energy. Making the membrane more porous and thinner (properties graphene is well suited to supply), helps increase the flux through the membrane and reduce the pressure requirements to reduce the amount of energy that the process requires.

Top Graphene News |

Graphene water treatment company raises £4 million

Arvia, a UK-based water and wastewater treatment company, has secured £4 million in its latest round of investment funding. The company developed its own graphene-based proprietary material called Nyex which removes organics, contaminants and micro-pollutants from wastewater and is regenerated in-situ in the novel organics destruction cell (ODC) process. The technology was spun-out of Manchester University’s School of Chemical Engineering.

Graphene helps in creating square ice at room temperature

An international team of researchers created a transparent nanosized graphene capillary to investigate the atomic structure of water trapped inside. They found that it is likely that square ice is very common on the molecular scale and present at the tip of many microscopic crack or pore in any material. The scientists explained that microscopic cracks are present everywhere, not only on this planet. So understanding that water on a nanoscale behaves so differently from the common bulk

water is important for better understanding of materials.

Graphene improves Alumina properties

The Spanish Graphenea, along with Russian and Spanish collaborators, showed that adding graphene to alumina improves the ceramic's wear resistance and decreases friction. The result is expected to soon find uses in real products, as graphene and its derivatives seem to be biocompatible and in addition carry a low cost.

Haydale increases graphene inks manufacturing capability and processing capabilities

Haydale recently ordered an additional significantly larger reactor, the HD200, as well as three Rotovac HD60 units for delivery by the end of June. The company also announced a new 230 m2 dedicated manufacturing area at its South Wales, UK facility to keep up with rapidly growing demand for these groundbreaking materials.

Talga Resources to construct a graphene pilot line in Germany

Talga Resources announced its plan to construct a graphene demonstration plant in central Germany. The plant is to produce between 100 t/y and 200 t/y of graphene, with feedstock sourced from Talga’s Swedish projects.

Rice scientists find simple ways to control graphene QDs from coal

Rice researchers have found a way to engineer coal GQDs for specific semiconducting properties in two separate processes. The researchers' work demonstrates precise control over the graphene oxide dots' band gap, the very property that makes them semiconductors.

Alabama Graphite finds graphene flakes on its property

Alabama Graphite announced that it has found naturally occurring flake graphene at its Coosa Property in Alabama, USA. The graphene was obtained using an innovative and cost effective process.

XG Sciences demonstrates impressive silicon graphene anode material

The American XG Sciences demonstrated full battery cell cycle stability, through more than 400 charge/discharge cycles, with a charge storage capacity of 600 mAh/gram over a broad voltage window in its next generation silicon graphene anode materials for lithium-ion batteries.

Graphene acts as a perfect separator in a novel light utilization device

Researchers at the Indian Institute of Science (IIS) designed a device based on graphene and metal nanoparticles that shows a significant response to light and is colour sensitive. This may be greatly beneficial for applications like ultra-sensitive photodetectors and efficient solar cells.

Caltech scientists claim novel way to make graphene fast, well and at room temperature

Researchers at the California Institute of Technology announce themselves the first to invent a technique that will allow fast, room-temperature production of long sheets of high-quality graphene. They also say the process is scalable, fast and results in good quality graphene. Until now, Caltech scientists have grown 1 centimeter graphene squares but plan to grow them to up to 4 inch. They will explore adding different molecules and compounds for varying effects.

Preheating gas precursors enhances CVD graphene production

Researchers from Israel's Bar Ilan University discovered that preheating the gas precursors in atmospheric-pressure CVD graphene production results in 100% reproducibility, and higher quality graphene sheets.

Humidity sensor made from graphene quantum dots and bacteria

Scientists at the University of Illinois at Chicago engineered a humidity sensor on a bacterial spore. They call it NERD, for Nano-Electro-Robotic Device. They've taken a spore from a bacteria and put graphene quantum dots on its surface, then attached two electrodes on either side of the spore. Then they change the humidity around the spore,causing the spore to shrink. As it shrinks, the quantum dots come closer together, increasing their conductivity, as measured by the electrodes.

Angstron Materials develops thermal foils for smartphones and electronic devices

Ohio-based Angstron Materials has developed a group of cost-effective thermal foil products that can be customized for handheld devices and other products. The company says that its foil sheets have been qualified for use by a major mobile electronics company. Such thermal foils can be used for the technology beneath devices' screens that conducts heat away from internal electronic components and batteries to help maintain optimal performance.

Send this to a friend |

Do you have a friend or a colleague that might be interested in Graphene technology? Forward this mail to update him on the

world of Graphene.

If you received this email from a friend, subscribe to this

newsletter here!