The Graphene-Info weekly newsletter

Published: Tue, 04/19/22

The Graphene-Info newsletter (April 19, 2022)

Cannot read this? View it online here

Zentek to work with EkoMed on graphene-enhanced PPE

Zentek has announced it has signed a definitive supply agreement with EkoMed Global, a globally integrated manufacturer and distributor of personal protective equipment (“PPE”), according to which Zentek will sell quantities of its proprietary ZenGUARD™ coating to EkoMed for use on EkoMed’s surgical masks and potentially other PPE in the future. The agreement also stipulates that Zentek will purchase surgical masks manufactured by EkoMed, to be treated with ZenGUARD™ coating and resold by Zentek.

“This agreement solidifies our relationship with an established and highly competitive player in the PPE space and a potential future innovation partner; both key elements of our global ZenGUARD™ sales strategy,” said Greg Fenton, CEO of Zentek. “As we seek to gain access to new markets, reliable, high-capacity and high-quality production along with additional sales channels for our patent-pending ZenGUARD™ technology are crucial. We believe this agreement will establish a solid foundation for Zentek to expand access to ZenGUARD™ globally. As important, we look forward to working with the EkoMed team to explore incorporating ZenGUARD™ into other PPE products currently being manufacturing and commercialized by EkoMed.”

Researchers design graphene nanocomposite temperature alarm sensor

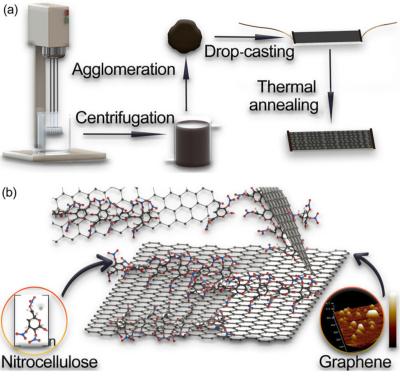

Researchers from The University of Manchester and Hubei University have integrated the electrical conductivity of graphene and the insulation of nitrocellulose to prepare a fire alarm sensor.

The graphene/nitrocellulose membrane remains electrically insulated in normal condition, but instantly turns conductive at high temperatures: Upon encountering flames, nitrocellulose decomposes rapidly as a reaction to the high temperature and induces a distinct transition in its electrical resistance, causing the transformation process of the alarm sensor from being electrically insulated to an electron conductive state.

Korean researchers fabricate nitrogen and sulfur co-doped graphene nanoribbons for enhanced potassium batteries

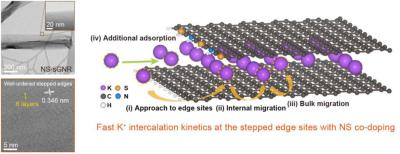

A research team, led by Professor Yu Seung-ho of the Department of Chemical and Biological Engineering at Korea University, Seoul National University's Professor Yuanzhe Piao and Sogang University's Professor Back Seo-in, has fabricate nitrogen and sulfur co-doped graphene nanoribbons with stepped edges, elucidating the migration barrier and enhancing the electrochemical performance of potassium batteries.

Potassium has shown promise for large-capacity non-lithium battery cells, because it is affordable, abundant, and has a low redox potential (-2.93V) close to that of lithium ion (-3.04V). Carbon-based nanomaterials, which are chemically stable and lightweight, are popular anode materials used in potassium batteries. However, the high energy barrier between electrochemical intercalation and deintercalation of potassium ions induces adsorption/desorption reactions, resulting in the storage of potassium ions only on the surface of carbon and lowering the energy density during battery assembly. As such, the smooth intercalation/deintercalation of potassium is extremely important in obtaining high-performance potassium batteries.

AGM reports its latest half-year financial results

Applied Graphene Materials (AGM) announced its interim results for the six months that ended on January 2022. Revenues were £46,000 (up from £42,000 in the previous half year period), while net loss was £1.9 million (up from £1.8 million).

Despite the low revenues and large loss, AGM's management says that there's a steady growth in potential pipeline projects - as these increased to 192 from 135 last year. The company also updates that it has been progressing with its developments for the battery and hydrogen fuel and storage industries.