The Graphene-Info weekly newsletter

Published: Tue, 11/02/21

The Graphene-Info newsletter (November 2, 2021)

Cannot read this? View it online here

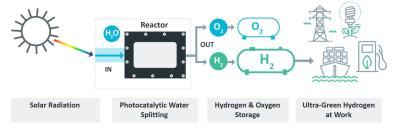

Sparc Technologies to develop an ultra-green hydrogen production process, with graphene coating

Sparc Technologies signed an agreement with its partner (and shareholder) the University of Adelaide to co-develop ultra-green hydrogen technology.

Sparc Tech, together with the University, will form a joint-venture called Sparc Hydrogen (72% owned by Sparc Tech). The new company will develop a process that will produce hydrogen based on thermo-photocatalysis, which uses the suns radiation and thermal properties to convert water into hydrogen and oxygen.

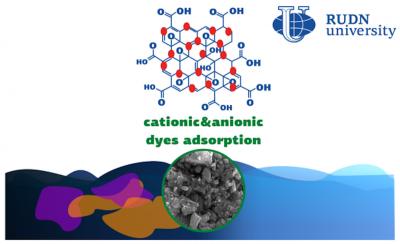

New GO–MnO2 nano-filter can efficiently clean water from toxic dyes

Researchers from Korea's University of Seoul, Russia's RUDN University and several India-based institutes have created a nano-filter for water purification from synthetic dyes. The graphene-based composite can reportedly remove up to 100% of harmful compounds from water, and it can be used up to seven times without losing efficiency. In addition, the synthesis of the nanofilter itself is economical and environmentally friendly.

Synthetic dyes are used in industrial chemistry and pharmaceuticals. They reach the wastewater together with other industrial waste and pollute the environment. Existing methods of water purification are not quite practical, as the proposed adsorbents are usually disposable and work slowly. Therefore, scientists continue to look for effective and eco-friendly solutions to this problem. The team in this recent work has proposed a reusable graphene-based nanocomposite that can quickly absorb dyes from water.

ZEN Graphene Solutions changes name to Zentek

ZEN Graphene Solutions has announced its plan to change its name to “Zentek Ltd.”. Zen Graphene Solutions was also formerly called Zenyatta Ventures, until it changed its name in January 2019.

Zen Graphene will remain trading with the same symbol, ZEN, at the TSX Venture Change.

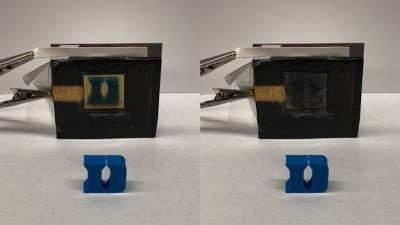

Graphene assists in creating new “smart-window-like” technology

Researchers at Duke University have used graphene to develop a unique electrochromic technology for smart window-like devices that can alternate between harvesting heat from sunlight and allowing an object to cool. The approach could promote HVAC energy savings savings.

A demonstration of the “smart-window-like” technology. Image credit: Po-Chun Hsu, Duke University

A demonstration of the “smart-window-like” technology. Image credit: Po-Chun Hsu, Duke University

The Duke team said that the new electrochromic tuning method does not have any moving parts and is continuously tunable.

Researchers use AI to develop efficient water desalination based on graphene nanopores

Researchers at Carnegie Mellon University have recently refined the water desalination process, with graphene nanopores obtained using artificial intelligence.

"The ions are so tiny, and if you want to remove them, you need to either boil, evaporate, and condense the water, or push it through membranes full of very tiny pores," explained Barati Farimani, an assistant professor of mechanical engineering at Carnegie Mellon University. The current desalination and separation process is very energy and time inefficient. To combat this, Barati Farimani and his team have used artificial intelligence (AI) agents to design an improved method in a week that would likely take decades. "Ideally," he explained, "the best membrane should be one atom thick, such as graphene, a single-layer sheet."

Lyten develops graphene-enhanced lithium-sulfur batteries for EVs

California-based company Lyten has developed a graphene-enhanced lithium-sulfur battery for electric vehicles. The battery reportedly achieved a higher gravimetric energy density than traditional lithium-ion and solid-state technologies. Lyten is said to have has previous collaborations with the US government for military projects.

The product was named LytCell EV and was designed to deliver three times the energy density of conventional lithium-ion batteries. The company reported 900 Wh/kg, precisely three times as much as the batteries in circulation today. Lyten Sulfur Caging is the name of the technology used in LytCell batteries to unlock the performance potential of sulfur by halting the advance of polysulfide, a cycle-life compromising factor that has so far prevented the practical use of Li-S in electric vehicles battery powered. Based on testing, a LytCell prototype reportedly proved to withstand more than 1,400 cycles very well.

G6 Materials reports its financial results for Q3 2021

G6 Materials (Formerly called Graphene 3D Lab) reported its financial results for Q3 2021 (which ended on August 31). The company's revenues in the quarter increased 55% from Q2, to reach $341,134. The increase is attributed to a stable increase in sales.

The company's net loss for the quarter improved by 37% to $571,194. The company's CEO, Daniel Stolyarov, says he is pleased with the increase in revenue, and he expects the company to continue the positive momentum in the future.

Researchers develop ultra-efficient 'clean' technique to control the properties of graphene

Researchers from Columbia University and collaborators from Korea's Sungkyunkwan University and Japan's National Institute for Materials Science have reported that graphene can be efficiently doped using a monolayer of tungsten oxyselenide (TOS) that is created by oxidizing a monolayer of tungsten diselenide.

The new results relied on a cleaner technique to manipulate the flow of electricity, giving graphene greater conductivity than metals such as copper and gold, and raising its potential for use in telecommunications systems and quantum computers.

Graphene oxide could improve aircraft fuel

A team of researchers at UBC Okanagan (UBCO), studying the burning rate of nanomaterials in liquid fuels, believe they have created a recipe for clean-burning, power-boosting aircraft fuel.

A droplet of fuel mixed with nanomaterials is ignited during an experiment in UBCO’s Combustion for Propulsion and Power Lab. Image credit: UBCO

A droplet of fuel mixed with nanomaterials is ignited during an experiment in UBCO’s Combustion for Propulsion and Power Lab. Image credit: UBCO

The team is investigating the combustion characteristics of microscopic graphene oxide inside fuel. Their experiment measures the ignition delay, burn rate and speed by which the graphene particles and fuel separate into smaller particles. “Working with our industry partner, ZEN Graphene Solutions, we are assessing how the burn rate of this mixture can potentially improve its combustion properties,” explains lead author and doctoral student Sepehr Mosadegh.

Directa Plus announces new line of high-tech trail shoes enhanced with its graphene technology

Directa Plus has stated that its graphene technology is being used in a newly-launched high-tech range of trail shoes.

Directa Plus said a specially developed graphene membrane is integrated into the lining of the norda 001 G+ Spike high-performance trail shoes, which are now available for consumer purchase.