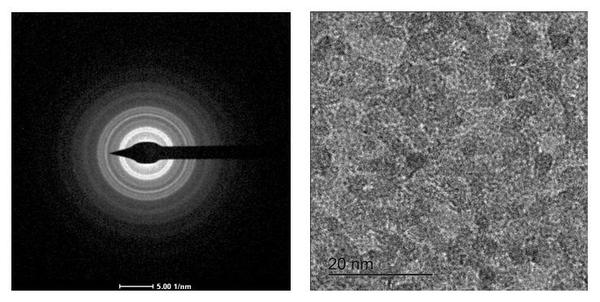

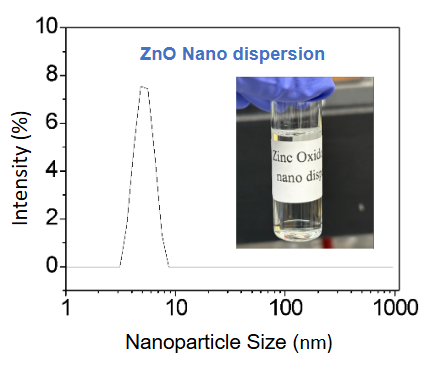

Dynamic light scattering (DLS) analysis of PINA zinc oxide (ZnO) nanoparticles are uniformly dispersed in isopropanol with a narrow size distribution centered around ~7–8 nm.

Use Cases Across Devices

Solar Cells

Stable ETL and HTL for Perovskite Solar Cells stack

Stable ETL and HTL for Indoor & Outdoor Organic

Photovoltaics (OPV) modules for IoT & smart sensors

OLEDs

Printable ETL and HTL layers for flexible and transparent display structures

Compatible with hybrid organic-inorganic architectures

Printed Sensors & Thin-Film Transistors (TFTs)

High uniformity ETL or active layers for large-area printable electronics

From Lab to Pilot to Production

What sets PINA’s nano ink

technology apart is its scalability. We design every formulation with the production line in mind — from the rheology and viscosity suited for precision coating, to the ink stability required for batch manufacturing, to the form factor flexibility needed for integration into existing platforms.

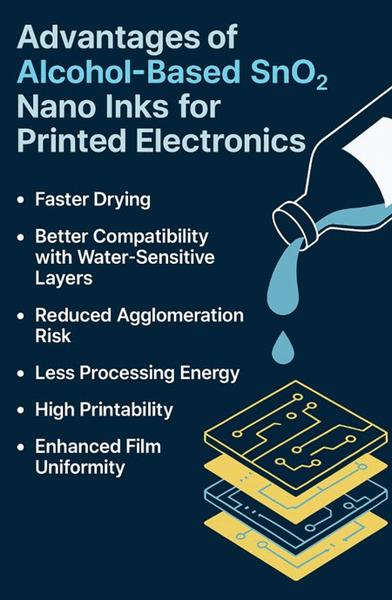

Conclusion

As Perovskite and OLED technologies edge closer to commercial viability, the materials used

in their architecture must evolve. Tin Oxide, Zinc Oxide, and NiO Nano Inks represent a critical enabler — offering stability, scalability, and performance in one printable package.

Whether you're building the next high-efficiency solar module or pioneering flexible OLED displays, PINA’s Nano Ink platform is ready to support your roadmap.

For datasheets, compatibility trials, or free samples, visit:

www.pinacreation.com or email us at info@pinacreation.com