Perovskite-Info weekly newsletter

Published: Tue, 04/04/23

The Perovskite-Info newsletter (April 4, 2023)

Cannot read this? View it online here

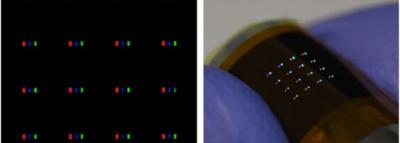

Researchers fabricate full-color flexible microLEDs using perovskite QDs

Researchers from Korea's KIMM institute have fabricated full-color flexible microLED devices, using blue LEDs and perovskite quantum dot color conversion layers. The demonstrated device featured 1 mm pixel pitch LEDs (25.4 PPI) and could be bent with a radius of 5 mm without being damaged.

The researchers used a perovskite-QD and siloxane composite using ligand exchanged PQD with silane composite followed by surface activation by an addition of halide-anion containing salt. Due to this surface activation, the researchers say that it was possible to construct the PQD surface with a silane ligand using a non-polar organic solvent that does not damage the PQD. As a result, the ligand-exchanged PQD with a silane compound exhibited high dispersibility in the siloxane matrix and excellent atmospheric stability.

IIT Roorkee and GIC Re to co-develop perovskite-based solar window technology

The Indian Institute of Technology Roorkee (IIT Roorkee) and General Insurance Corporation of India (GIC Re) have signed a partnership agreement to develop perovskite-based solar window technology that will enhance the solar power generation in India and lead to greater sustainable development.

The new solar window technology will be designed and developed by Prof. Soumitra Satapathi from the Department of Physics (IIT Roorkee) and his team. Under the program, semi-transparent perovskite solar cells will be developed for building integrated photovoltaics (BIPV). The new window solar technology will harness electricity during the daytime and reduce reliance on traditional electricity sources.

SEKISUI CHEMICAL and JERA announce commencement of joint demonstration test of perovskite solar cells

SEKISUI CHEMICAL has announced that it commenced a demonstration test to install film-type perovskite solar cells at thermal power stations together with JERA on March 24, 2023.

SEKISUI CHEMICAL has created a 30 cm-wide roll-to-roll manufacturing process utilizing its original “sealing, film formation, materials and process technology,” and have confirmed 10 years equivalent of outdoor durability, which is said to be critical to the development of film-type perovskite solar cells. Furthermore, this manufacturing process has reportedly been successfully used to produce film-type perovskite solar cells with a power generation efficiency of 15%. Development is being accelerated to further improve durability and power generation efficiency, as well as to establish manufacturing technology for 1 m-wide rolls.

Researchers examine a perovskite-based electrolyte developed for SOFCs

Solid oxide fuel cells, or SOFCs, are a type of electrochemical device that generates electricity using hydrogen as fuel, with the only 'waste' product being water.

To potentially accelerate the development of more efficient SOFCs, a research team from Kyushu University, Yamagata University and Kyushu Synchrotron Light Research Center has uncovered the chemical innerworkings of a perovskite-based electrolyte developed for SOFCs. The team combined synchrotron radiation analysis, large-scale simulations, machine learning, and thermogravimetric analysis, to uncover the active site of where hydrogen atoms are introduced within the perovskite lattice in its process to produce energy.

Researchers design a slot die-coated perovskite solar panel with improved efficiency retention

Scientists from Nanyang Technological University, along with their collaborators, have fabricated a slot die-coated perovskite solar panel that reportedly offers remarkable efficiency retention.

The researchers used a hydrophobic, all-organic salt known as fluorinated anilinium benzylphosphonate (FABP) to modify the top surface of large area slot-die coated methylammonium (MA)-free halide perovskite layers. The salt acts as a molecular lock that is able to bind to both anion and cation vacancies, which significantly increases the materials' intrinsic stability.

Greatcell Australia and First Graphene explore graphene enhancements to perovskite solar cells

It was recently reported that Greatcell Australia is working with graphene company First Graphene on graphene enhancements to perovskite solar cell technology.

Greatcell Australia has reportedly established a pilot plant in New South Wales and is in the advanced stages of testing its range of perovskite solar cells (PSCs) with manufacturers around the world. Greatcell is aiming to fit its modular production lines into 40-foot shipping containers, due in part to the easier assembly and reduced number of steps to produce PSCs compared to silicon solar cells.

Metalgrass LTD

9 Har Tsin St.

Kfar Sava Hasharon 4430809

ISRAEL

Unsubscribe | Change Subscriber Options