Perovskite-Info weekly newsletter

Published: Tue, 10/11/22

The Perovskite-Info newsletter (October 11, 2022)

Cannot read this? View it online here

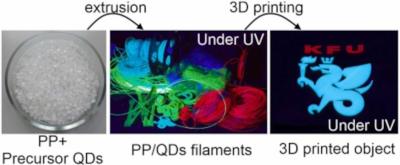

New method creates perovskite composites for 3D printing

Researchers from Russia's Kazan Federal University have reported on a new method for the fabrication of polypropylene/metal halide perovskites composite in one single step by co-extrusion of the perovskite precursors with polypropylene. Perovskite quantum dots are formed in-situ, and are uniformly distributed in the polymer matrix.

The team said that the material demonstrated high quantum yield and unprecedented stability at ambient conditions. The team further demonstrated that an extruded strand can be used directly as a filament for 3D printing technology. The developed method is simple, has literally no waste, and is unlimitedly scalable. It offers a way to efficiently solve the problem of stability of perovskites, simultaneously involving them into additive manufacturing technologies.

Researchers test halide perovskites' suitability for battery applications

University of Freiburg researchers have evaluated how suitable halide-perovskites are for advanced photoelectrochemical battery applications. The recent paper unveiled important findings that could influence the use of organic-inorganic perovskites as multifunctional materials in integrated photoelectrochemical energy harvesting and storage devices.

Importantly, the research has revealed the tendency for 2-(1-cyclohexenyl)ethyl ammonium lead iodide (CHPI) perovskites to dissolve in highly polar electrolytes commonly employed in current lithium-ion batteries. The selection of low polarity electrolytes stabilizes the CHPI electrode material, leading to purely capacitive behaviors in batteries and minimizing lithium-ion intercalation. However, when applying a galvanostatic charge whilst the perovskite electrode material is in contact with electrolyte leads to photo corrosion and CHPI phase dissolution.

Researchers use slot dye coating to fabricate perovskite/silicon tandem solar cells with optimized bandgap

Researchers from Helmholtz-Zentrum Berlin (HZB) have demonstrated the scalable fabrication of perovskite/silicon tandem solar cells with optimized bandgap using the slot-die coating method. The team used slot-die coating for an efficient, 1.68 eV wide bandgap triple-halide (3halide) perovskite absorber, (Cs0.22FA0.78)Pb(I0.85Br0.15)3 + 5 mol % MAPbCl3. The team demonstrated that the fabrication route is suitable for tandem solar cells without phase segregation.

The researchers successfully fabricated a triple-halide perovskite film with top cell optimized bandgaps, high PL quantum yield (PLQY), and improved film quality using the slot-die coating method. They have also efficiently integrated halide perovskites with industrial silicon bottom cells in a tandem architecture, demonstrating the potential of fabricating industrially relevant and scalable perovskite solar cells.

Researchers examine the effect of humidity on hardness and elastic modulus (E) of lead halide perovskite single crystals

Researchers from Israel's Bar-Ilan University and Weizmann Inst. of Science have measured the effect of humidity on hardness and elastic modulus (E) for two series of lead halide perovskite single crystals. The results indicated the influence of hydrogen (H)-bonding, bond length, and polarization of the ions in lead halide perovskite single crystals.

The team detected an inverse relation between hardness and modulus, which was strengthened with increased humidity. Their findings shed light on the material's distinct structure and properties at the atomic scale. The conclusion of this work was based on the evaluation of outcomes of various nano-indentation techniques that differentiated between surface and bulk E and explored different manifestations of hardness.

Researchers develop perovskite solar cell with over 20% efficiency that generates electricity for more than 1,000 continuous hours

Researchers from Japan-based National Institute for Materials Science (NIMS) recently developed a durable 1cm2 perovskite solar cell capable of generating electricity for more than 1,000 continuous hours at a photoelectric conversion efficiency (i.e., power generation efficiency) of more than 20% in exposure to sunlight.

As this solar cell can be fabricated on the surface of a plastic material at approximately 100°C, this technique could have great potential for developing light, versatile solar cells.

Metalgrass LTD

9 Har Tsin St.

Kfar Sava Hasharon 4430809

ISRAEL

Unsubscribe | Change Subscriber Options