Perovskite-Info weekly newsletter

Published: Tue, 07/26/22

The Perovskite-Info newsletter (July 26, 2022)

Cannot read this? View it online here

Researchers achieve 23.5% efficiency for a perovskite-silicon tandem cell using a special polymeric film

Researchers from Ulsan National Institute of Science and Technology (UNIST) in South Korea and the University of Pittsburgh in the U.S have reported a power conversion efficiency of 23.5% in a perovskite-silicon tandem solar cell by applying a special textured anti-reflective coating (ARC) polymeric film.

The team prepared the multifunctional film with phosphor particles measuring 10 μm in diameter. They are able to block ultraviolet (UV) light and silicon dioxide (SiO2) nanoparticles with a diameter of 10 nm to increase the ability of a perovskite-silicon tandem solar cell to absorb visible light. The scientists explained that the phosphors increase the reflectance of the ARC film, due to their large particle size, thus causing a backward light scattering issue. This in turn is compensated by the addition of the spherical SiO2 nanoparticles.

Researchers reach 16.5% efficiency with p-i-n perovskite solar cell on steel substrate

Researchers from the Eindhoven University of Technology, the Netherlands Organization for Applied Scientific Research (TNO), and Indian steel manufacturer Tata Steel recently fabricated an inverted perovskite solar cell based on a polymer-coated steel substrate that can achieve a power conversion efficiency approaching that of non-inverted reference solar cells with a similar stack design.

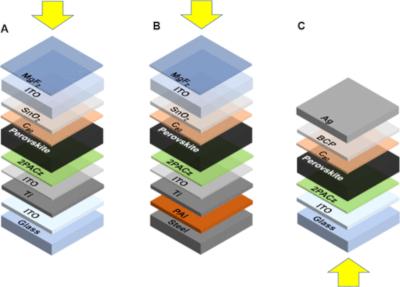

Substrate (A and B) and superstrate (C) p–i–n solar cells on glass (A and C) and steel (B). Image from ACS Publication study

The cell has a p-i-n structure and relies on nickel-plated steel coated with a polyamide-imide (PAI) planarization layer, which serves as an insulating layer. The researchers used an opaque titanium electrode covered with a thin sputtered indium tin oxide (ITO) layer to enable the binding of the phosphonic acid anchoring groups of the monolayer based on a perovskite known as 2PACz, which serves as a hole-collecting electrode.

Researchers achieve 18.4% efficiency for 4T flexible perovskite-CIGS tandem mini-module

Researchers from Switzerland's Federal Laboratories for Materials Science and Technology (EMPA) and École Polytechnique Fédérale de Lausanne (EPFL) have designed a four-terminal tandem mini-module based on perovskite and copper, indium, gallium and selenium (CIGS) with an aperture area of around 2 cm2, and a geometric fill factor of over 93%.

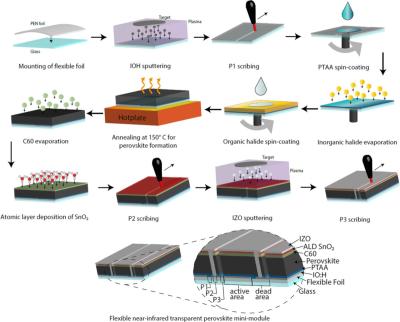

Processing sequence of flexible NIR-transparent perovskite mini-module. Image from RRL Solar

The team reports that the key to efficient flexible perovskite-CIGS tandem modules is the development of near-infrared (NIR) transparent perovskite solar modules on a flexible polymer foil. To achieve these results, the researchers had to overcome the challenges of laser patterning on flexible substrates to realize the first all-laser scribed monolithically interconnected NIR-transparent perovskite mini-modules on polymer film. The perovskite mini-module used in the tandem panel was fabricated on a flexible polyethylene napthalathe (PEN) substrate mounted to a glass substrate in a p–i–n device architecture. This configuration, according to the research team, shows reduced absorption in the NIR region.

Novel lamination process enables 20% efficiency of monolithic perovskite-silicon tandem cells

Researchers from the Karlsruhe Institute of Technology (KIT) and the Forschungszentrum Jülich GmbH in Germany have developed a monolithic perovskite-silicon solar cell with a power conversion efficiency of 20%, using a novel lamination approach.

The team investigated how this lamination process can be applied to perovskite/silicon tandem technology. They explained that the solar cells are the first prototypes and that lamination is a suitable alternative fabrication method for monolithic perovskite/silicon tandem solar cells. The lamination approach, they said, is particularly interesting for perovskite-based PV, as it notably increases the degree of freedom in the choice of materials and accessible deposition techniques.

Metalgrass LTD

9 Har Tsin St.

Kfar Sava Hasharon 4430809

ISRAEL

Unsubscribe | Change Subscriber Options