Perovskite-Info weekly newsletter

Published: Tue, 07/12/22

The Perovskite-Info newsletter (July 18, 2022)

Cannot read this? View it online here

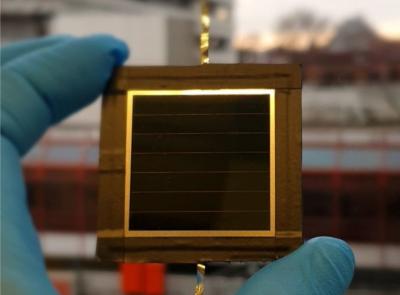

Researchers from EPFL and CSEM achieve 31.25% efficiency for tandem perovskite-silicon solar cell

Researchers from the Swiss Center for Electronics and Microtechnology (CSEM) and the École polytechnique fédérale de Lausanne (EPFL) have reported a power conversion efficiency exceeding 30% for a 1 cm2 tandem perovskite-silicon solar cell, which represents a world record for a PV device of this kind. The team achieved an efficiency of 30.93% for a 1 cm2 solar cell based on high-quality perovskite layers from solution on a planarized silicon surface and an efficiency of 31.25% on a cell of the same size and fabricated with a hybrid vapor/solution processing technique compatible with a textured silicon surface.

“These results constitute two new world records: one for the planar and one for the textured device architecture,” the researchers explained, noting that both efficiencies were certified by the US Department of Energy's National Renewable Energy Laboratory (NREL). “The latter approach provides a higher current and is compatible with the structure of current industrial silicon solar cells”. Unfortunately, the researchers did not disclose technical details on how they improved the efficiency of both devices.

ZSW designs new process for perovskite solar cell production using environmentally friendly precursor solvents

The Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) has made progress towards the goal of coating large-area perovskite solar cells on an industrial scale using a process that uses more benign solvents than available hazardous solvents like dimethylformamide. The team of researchers developed a coating process for perovskites that uses a single ecofriendly solvent, dimethyl sulfoxide. The ZSW team applied this method to produce a solar cell nearly as efficient as cells made with the toxic solvent.

Perovskite precursors have to first be dissolved so they can be applied in uniform layers to the substrate. This requires solvents that usually contain dimethylformamide (DMF), which is hazardous to health and the environment. This toxicity hampers efforts to scale this process up to industrial production. Manufacturers would have to produce and dispose of larger quantities of the solvent and take even more stringent occupational safety measures, also causing costs to rise. For these reasons, many researchers and manufacturers are in search of environmentally compatible solvents that are suitable for industrial applications. This use case requires chemical properties that very few substances exhibit. Dr. Jan-Philipp Becker, the head of the ZSW’s Photovoltaics: Materials Research department, worked with his team to investigate pure dimethyl sulfoxide (DMSO) to see if it could serve this purpose.

Novel spectroscopic approach for assessing the impact of chemical alterations of the A-cation on perovskite electronic structure

Researchers from Uppsala University, Stockholm University, Deutsches Elektronen-Synchrotron DESY, KTH Royal Institute of Technology and Tata Institute of Fundamental Research have used the element selectivity of high-resolution X-ray spectroscopy and density functional theory to uncover a previously hidden feature in the conduction band states, the σ-π energy splitting, and found that it is strongly influenced by the strength of electronic coupling between the A-cation and bromide-lead sublattice.

These findings provide an alternative mechanism to the commonly discussed polaronic screening and hot phonon bottleneck carrier cooling mechanisms. The new work emphasizes the optoelectronic role of the A-cation, provides a comprehensive view of A-cation effects in the crystal and electronic structures, and outlines a broadly applicable spectroscopic approach for assessing the impact of chemical alterations of the A-cation on perovskite electronic structure.

Researchers design two-terminal all-perovskite tandem solar modules with a 19.1% efficiency

Researchers at the Karlsruhe Institute of Technology (KIT) in Germany have fabricated a spin-coated, two-terminal, all-perovskite tandem solar module with an aperture area of 12.25 square centimeters and a geometric fill factor of 94.7%. The team said that laser-scribed two-terminal all-perovskite tandem (2TPT) solar cells have attracted attention in recent years, as they combine a wide bandgap perovskite top subcell with a narrow-bandgap perovskite bottom subcell.

The scientists used a 23-5% efficient 2TPT solar cell based on perovskite and copper/indium/selenium (CIS) thin-film, which they first announced in June. It has an open-circuit voltage of 1.59 V, a short-circuit current of 19.4 mA cm–2, and a fill factor of 75.5%.

Researchers examine the environmental performance of perovskite-on-silicon tandem solar cells

A team of scientists from Technische Universität Berlin, Oxford PV Germany, German Philipps-Universität Marburg, Helmholtz Zentrum Berlin (HZB) and Oxford PV UK has, for the first time, assessed the environmental performance of industrially produced perovskite-on-silicon PV modules. Understanding the environmental impact of solar PV modules across their entire lifecycle is essential for the design of more sustainable solar energy systems. However, lifecycle assessment of perovskite-on-silicon PV modules has so far relied heavily on data from laboratory and test facilities rather than manufacturers.

The researchers conducted a comprehensive lifecycle assessment of a perovskite-on-silicon module across a number of categories including global warming potential, water consumption, human and marine toxicity, and metals usage. They assessed the materials and energy input for a module’s ‘cradle to gate’ lifecycle, covering all materials and energy input for wafer production, manufacture of the perovskite cell, and module production. The researchers then weighed up the environmental impact of the tandem module against the electricity generated over its lifetime.

Metalgrass LTD

9 Har Tsin St.

Kfar Sava Hasharon 4430809

ISRAEL

Unsubscribe | Change Subscriber Options