Perovskite-Info weekly newsletter

Published: Tue, 07/05/22

The Perovskite-Info newsletter (July 5, 2022)

Cannot read this? View it online here

Researchers design an inverted perovskite-silicon tandem solar cell with 29.3% efficiency

Researchers at King Abdullah University of Science and Technology (KAUST) and Max Planck Institute have developed an inverted perovskite-silicon tandem solar cell with a 1 nm thick interlayer based on magnesium fluoride (MgFx) placed between the perovskite layer and the hole transport layer (HTL), in order to reduce voltage losses while still retaining 95.4% of its initial efficiency after 1,000 hours.

The scientists stated that the charge transport and recombination interfaces could be carefully tuned with MgFx interlayers, enabling a certified efficiency of 29.3%. Currently, the record perovskite/silicon tandem solar cell is a 29.8% device that was recently developed by scientists at Helmholtz-Zentrum Berlin (HZB) in Germany. The scientists fabricated the new cell with a sub-cell based on crystalline silicon wafers with double-side texture, which they say reduces front reflection while improving light trapping. They also placed the MgFx interlayer at the electron-selective top contact.

Hanwha Solutions one step closer to mass production of perovskite solar cells

Korea-based Hanwha Solutions has announced that it has come one step closer to mass-producing perovskite solar cells. Hanwha Q CELLS, the solar power business division of Hanwha Solutions, recently succeeded in developing a 6-inch solar tandem cell.

Hanwha Solutions has reportedly overcome the disadvantages of small area cells, which were a constraint on mass production of perovskite batteries, paving the way for mass production of next-generation solar cells. The company is currently working on performance improvement of the solar tandem cell, with the goal of beginning mass production of perovskite batteries in 2025. Hanwha Q CELLS said it is preparing for mass production of the tandem cells.

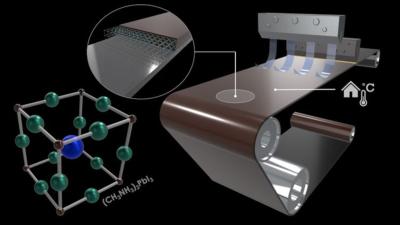

Researchers develop an approach for the fabrication of large-scale and high-quality perovskite films

University of Surrey researchers have produced solar cell building blocks out of perovskite ink. Current inks do not guarantee seamless transitions on an industrial scale, as the manufacturing process needs to be highly controlled and optimized. That is why the team developed a perovskite ink that presents a fast and reproducible way to fabricate these solar cell building blocks on a mass scale.

A Q&A with perovskite material producer TCI Chemicals

Tokyo Chemical Industry (TCI) is a global supplier of laboratory chemicals and specialty materials. TCI is a leading the next-generation solar technology industry by providing high-quality and reliable materials, including metal halide perovskite precursors such as lead/tin halides and organic onium salts, as well as carrier transporting materials.

TCI recently launched hole selective self-assemble monolayer (SAM) forming agents, 2PACz [Product Number: C3663] , MeO-2PACz [Product Number: D5798] and Me-4PACz [Product Number: M3359] for high performance perovskite solar cells. The company is getting ready to launch some more related materials in 2022. We thought it'd be a good time to catch up with TCI, and have conducted a Q&A with TCI’s Institute for Material Science's general manager, Dr. Taro Tanabe.

Researchers fabricate perovskite-silicon tandem solar cell with 27.6% efficiency

A research group that includes scientists from Chinese module manufacturer JinkoSolar, Australian National University, the Beijing Institute of Technology and Peking University has developed a monolithic perovskite-silicon n-type tandem solar cell based on tunnel oxide passivated contacts (TOPCon) tech for the bottom cell.

“We fabricate the perovskite sub-cell conformally on the damage-etched front surface to mitigate the negative impacts of rough c-Si substrates, thus preventing shunt paths across carrier transport layers, absorber layers, and their interfaces in relevance,” the scientists said, noting that they followed a standard wafering and etching process that is commonly used in the PV industry.